What is coffee processing ?

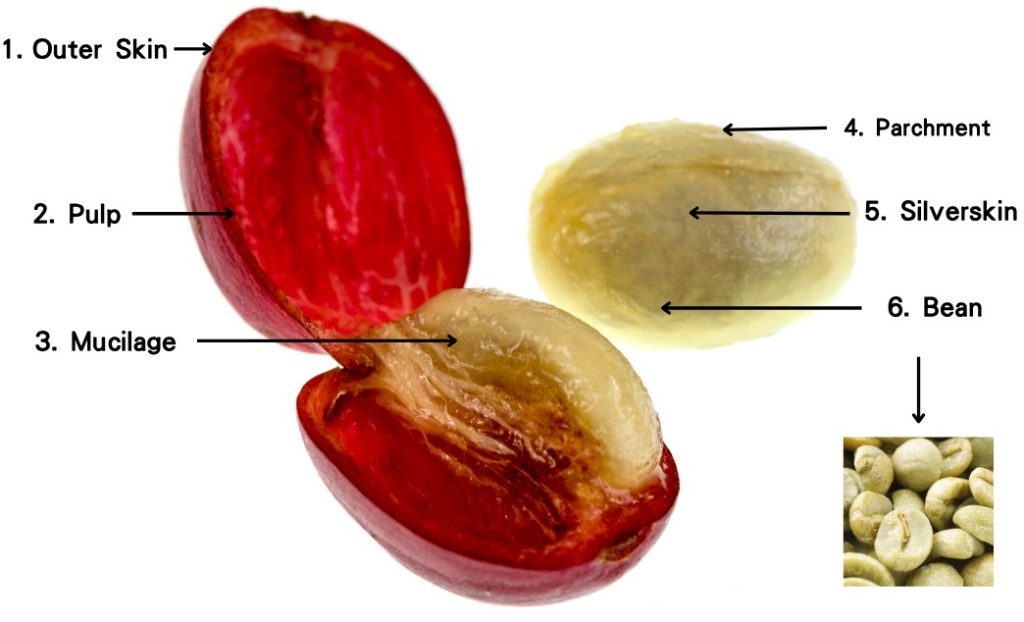

Coffee processing is the set of steps that a coffee bean goes through after being harvested, turning the coffee cherry into green beans ready for roasting. In this process, different layers of the fruit; including the skin, the pulp, the mucilage (a sugary and pectin-rich layer) and the parchment are removed from the bean.

This stage not only determines the final quality of the coffee, but also plays a direct role in the flavor, aroma and even the shelf life of the product.

Main stages of coffee processing

- Harvesting and sorting cherries: The process starts with harvesting ripe cherries, since the best quality comes when the fruit is picked at peak ripeness. Unripe or defective beans are removed through flotation or mechanical sorting.

Fermentation and drying: Depending on the method (Washed, Natural, or Honey), beans undergo fermentation to break down the fruit layers and form the cup profile. They are then dried on raised beds or patios until moisture content reaches about 10–12%.

Cleaning and preparing green coffee beans: In the final stage, the dried husk or remaining fruit layers are removed. Beans are sorted by size and quality, resulting in uniform green coffee ready for export and roasting.

Why is coffee processing important ?

Processing is the bridge between farming and roasting. Every detail or mistake at this stage can dramatically change the final taste of coffee. A well-controlled fermentation can create a clean and balanced acidity, while poor management can lead to unpleasant flavors like sourness or mold. For producers, good processing means differentiation in the market and higher product value.

Three key factors influenced by processing:

Fermentation Control: Determines how long the mucilage stays in contact with the bean and how much acid and alcohol is produced.

Drying Process: The final moisture content of the bean directly affects stability and shelf life.

Defect Rate: More precise methods reduce the chance of undesirable flavors such as moldy or earthy notes.

Which coffee processing method tastes best: Washed, Natural, or Honey ?

Coffee processing after harvest is one of the most crucial stages in production, directly affecting the flavor, aroma and final quality of the drink. The type of processing can change sweetness, acidity, body, and flavor complexity, as well as influence consistency across different harvests.

That’s why choosing the right method is key; not only for producers but also for consumers. The three most common methods worldwide are Washed (Wet Process), Honey Process, and Natural (Dry Process), each shaping coffee flavor in its own unique way.

Why is Washed coffee the best choice for specialty ?

Because washed process highlights origin characteristics with higher acidity and clean cup, making it a benchmark for specialty coffee.

What’s the difference between Yellow and Black Honey ?

Yellow Honey leaves less mucilage, producing a cleaner profile closer to washed coffee. Black Honey keeps the most mucilage, leading to longer fermentation, heavier body, and fruitier flavors closer to naturals.

Why do some naturals taste winey or alcoholic ?

Because fermentation happens on the whole cherry, yeast activity can create wine-like or alcoholic notes.

Stages of Washed Coffee Processing

Pick the cherries when fully ripe and depulp immediately to prevent overheating and prolonged fermentation that would spoil the aroma and flavor of the beans.

Soak the cherries in tanks full of water to separate infested cherries and foreign matter.

Only healthy and fully mature cherries are fed into the pulping machine.

After pulp removal, beans coated with mucilage are transferred into a fermentation tank for several hours of controlled fermentation.

Alternatively, the mucilaginous beans can be washed with pressurized water to remove the mucilage, making fermentation unnecessary.

The beans are then dried completely and made ready for market.

The resulting beans have very high cup quality, but processing is expensive and requires skilled labor.

Key Characteristics:

High flavor intensity

Clean cup with no off-flavors

High acidity

Light to medium body

Common notes: citrus, floral

The washed process is considered the benchmark for specialty coffee due to its high level of control and consistency in quality.

Washed Processing and Its Impact on Coffee Flavor and Quality

In the washed process, the skin and pulp of the coffee cherry are first removed, and the beans with the mucilage (a sticky, sugary layer) undergo fermentation. Fermentation softens the mucilage, which is then completely washed away. Afterward, the beans are dried, resulting in coffee with high flavor clarity and free from undesirable notes.

Stages of Natural or dry Coffee Processing

Coffee cherries are spread out under the sun until they are completely dried.

The beans are then hulled (removal of pericarp) either with machines or with a pestle and mortar.

The dried pericarp chaff is removed by winnowing, followed by hand-picking.

Proper drying facilitates hulling and winnowing.

The dry method is simple, has low capital cost per unit, and does not require skilled labor.

However, the long period required for proper drying depends heavily on weather conditions.

In addition, the beans are of lower quality, with wide fluctuations in quality among different growers.

Key Characteristics:

Strong fruity notes (berries, peach, grape), sometimes wine-like

Mild to balanced acidity

Heavier body compared to other methods

Higher risk of defects if poorly managed

Successful profiles: fruity, sweet, and complex

In natural processing, more sugars and aromatic compounds are preserved within the bean, resulting in higher sweetness and flavor intensity.

Natural Processing and Its Role in Creating Fruity Flavor and Heavier Body

The natural or dry processing method is one of the oldest in the world and is still preferred by many coffee farmers. Its main difference from other methods is that the entire coffee fruit is dried along with the beans. In this process, the beans are still inside the fruit, which allows for natural fermentation and the transfer of sugars and fruity flavors to the beans. In this method, the coffee is spread out on large raised beds or open areas for several weeks. During this time, it must be turned and cared for regularly. It must also be covered or covered to protect it from weather conditions (rain or strong winds).

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Stages of Natural or dry Coffee Processing

Coffee cherries are spread out under the sun until they are completely dried.

The beans are then hulled (removal of pericarp) either with machines or with a pestle and mortar.

The dried pericarp chaff is removed by winnowing, followed by hand-picking.

Proper drying facilitates hulling and winnowing.

The dry method is simple, has low capital cost per unit, and does not require skilled labor.

However, the long period required for proper drying depends heavily on weather conditions.

In addition, the beans are of lower quality, with wide fluctuations in quality among different growers.

Key Characteristics:

Strong fruity notes (berries, peach, grape), sometimes wine-like

Mild to balanced acidity

Heavier body compared to other methods

Higher risk of defects if poorly managed

Successful profiles: fruity, sweet, and complex

In natural processing, more sugars and aromatic compounds are preserved within the bean, resulting in higher sweetness and flavor intensity.

Honey Process: Balance Between Sweetness and Clarity

In this method, the skin of the fruit is removed but some of the mucilage remains on the bean. This sugary layer provides the natural sweetness in the final drink.

Honey processing can be considered the meeting point of two worlds; on the one hand, it brings the clarity and flavor order of the washed method, and on the other, the fruity complexity and richness of the natural method. This combination makes honey a great playground for roasters and baristas to create new profiles.

In recent years, the use of African raised beds (mesh tables that allow air circulation) has become popular around the world, from Ethiopia (the birthplace of the method) to Latin America and Asia ; because they dry the coffee more evenly and reduce the risk of mold (as air passes both above and below the coffee).

Some producers have used solar dryers or greenhouse-like polytunnels; transparent structures that retain heat but protect the coffee from rain. This method allows coffee to be dried in humid or sparsely-rained areas.

Mechanical dryers (such as guardiolas) are also now being used more strategically: instead of drying the beans completely in the sun for several days (which comes with weather hazards), a farm might first dry the coffee briefly in the sun to develop flavor, then complete the drying process in a temperature-controlled mechanical dryer to quickly bring the beans to a safe moisture content. This combined approach can reduce time, prevent spoilage, and use less energy than purely mechanical drying.

Carbonic Maceration: Inspired by Winemaking

Rooted in the wine industry: fermentation of whole cherries in sealed tanks.

Controlled conditions: beans are placed in stainless steel tanks with one-way valves that allow gas to escape without oxygen entering.

Flavor characteristics: strong fruity aromas, wine-like notes, fruity drinks, and sometimes complex profiles with spice or floral notes.

Key difference: fermentation happens with all layers of the cherry (skin and pulp) before drying or further processing.

Anaerobic Process: Controlled Fermentation Without Oxygen

General definition: any fermentation in a sealed tank without oxygen.

Flexibility: can be done on depulped beans (after removing skin and pulp) or even on whole cherries.

Fermentation management: anaerobic conditions allow much longer fermentation than traditional methods and reduce the risk of over-fermentation or undesirable microbial growth.

Flavor profile: very fruity, sweet, sometimes candy-like or soda-like. In some cases, the result may be close to washed coffees without dramatic differences.

New Coffee processing methods

Conclusion: Choosing the Right Processing Method

One of the biggest challenges for producers is choosing a method that not only preserves flavor quality and consistency in the cup but also ensures economic sustainability and reliable return on investment.

Washed: Safe choice for specialty markets, but more costly and water-intensive.

Natural: Attractive for its fruity profile and lower costs, but with higher risks in consistency.

Honey: A balance between the two, with market potential and reduced water usage.

The right choice depends on your brand’s goals, production capacity, and target market. If you are deciding on the best processing method, contact our specialists now📞!

A smart decision can make the difference between ordinary coffee and a leading brand in the specialty market.