Sensory Attributes like Gloss and Snap: What Drives Consumer Preference?

When we break a chocolate bar and hear that clean snap, or feel it melt smoothly on our tongue with a glossy finish, our brain associates these sensations with quality.

These sensory cues are directly linked to the Beta 5 (βV) crystal form of cocoa butter.

Studies have shown that chocolates with higher proportions of stable crystal forms (especially Form V) offer superior sensory appeal and are consistently favored in blind taste tests.

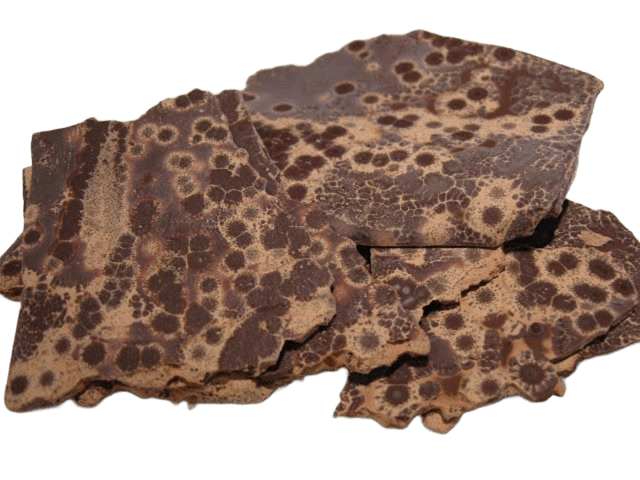

In contrast, chocolates dominated by less stable forms (e.g., Form IV or VI) lack gloss and have a softer, duller break, affecting first impressions and final selection at point of sale.

How Does the Beta5 Form Prevent Fat Bloom and Maintain Shelf Appearance?

Fat bloom the whitish, chalky surface poor tempering and unstable polymorphs. Ensuring proper formation of the Beta5 Form (βV) significantly reduces bloom risk and enhances surface stability.

Industry studies indicate that chocolates with a strong βV profile remain visually stable for up to 9 months at 20–25 °C.

Without βV dominance, even premium chocolate is prone to bloom, regardless of packaging or storage conditions.

Glossy finish, a clean snap sound, and visual consistency all point to a strong presence of the βV form.

🔗 ACS Crystal Growth & Design – Structural Insights into Cocoa Butter Form V

The Commercial Value of the Beta5 Form in Product Success

In the competitive world of chocolate, it’s no longer just about taste. visual appeal, snap, and surface stability heavily influence consumer choice. The Beta5 Form (βV crystal )plays a crucial role in delivering this complete sensory experience.

Understanding βV Polymorphism in Cocoa Butter: The Role of TAG Structure and Form Control

Structure of cocoa butter triglycerides (POP, POS, SOS) and their role in the formation of the beta5 form

Cocoa butter mainly contains three types of triacylglycerols (TAGs ):

POP (1-palmitoyl-2-oleoyl-3-palmitoyl glycerol)

POS (1-palmitoyl-2-oleoyl-3-stearoyl glycerol)

SOS (1-stearoyl-2-oleoyl-3-stearoyl glycerol)

These TAGs dictate the melting point, packing behavior, and polymorphic tendencies of cocoa butter. The Beta5 form (βV) typically crystallizes under controlled conditions from a balanced POS/SOS ratio and precise thermal cycling.

Form V vs. Form IV: Why the Transition Matters

Cocoa butter can crystallize into six main polymorphic forms (I to VI), each differing in structure, thermal stability, and melting point. Among these, the transition from unstable forms to more stable ones. especially from Form IV to βV (Form V) is critical for delivering the ideal texture and sensory qualities in chocolate production.

Form IV: Common But Unstable

Form IV, which frequently appears in industrial chocolate lines, melts at approximately 27 °C. While easy to achieve, it is relatively unstable under ambient conditions. Over time, chocolate made with Form IV tends to transition into unwanted forms, resulting in surface dullness and fat bloom.

Form V (βV): The Gold Standard in Chocolate Crystallization

By contrast, Form V melts at around 31–32 °C and is considered the most desirable from a thermodynamic and sensory perspective. It offers superior gloss, clean snap and longer shelf stability. key factors in consumer perception and market success.

How to Achieve the IV to V Transition :

Reaching βV requires precise tempering control. This process typically involves three stages :

Complete melting of all polymorphic forms

Controlled cooling to promote seed crystal formation

Final temperature adjustment to eliminate unstable forms and promote βV dominance

If this sequence is disrupted or incomplete, bloom and product rejection are likely to follow in the short term.

Thermal Range and Crystallization Behavior of βV

The βV form typically emerges after cooling cocoa butter to 26–28 °C, followed by reheating to a controlled range of 31–33 °C.

This cycle helps eliminate lower forms (like β′) and promotes stable βV crystallization.

Real-time tempering can be monitored via SFC (Solid Fat Content) profiling or thermal analysis tools like DSC to ensure βV formation is dominant throughout the batch.

What Is Fat Bloom After Packaging? What’s the Most Effective Way to Prevent It ?

The most effective method for stabilizing the βV form (Beta 5) and preventing fat bloom is precise tempering combined with the use of seed crystals, along with controlled storage temperatures.

Chocolate must be tempered in three stages for optimal βV formation:

(50–45 °C → 27 °C → 31–32 °C)Use seed crystals to enhance nucleation and promote stable βV formation.

Thermal fluctuation after packaging is a major trigger of bloom. Holding chocolate between 16–20 °C is critical to stability.

So post-packaging, the best combination is:

accurate cold chain + tight tempering + seed addition → this can reduce fat bloom occurrence by up to 80% if βV is properly formed.

3-step tempering (50–45 °C → 27 °C → 31–32 °C)

In continuous production systems, precise thermal profiling is essential for forming the βV (Beta 5) polymorph. The optimal three-step tempering cycle includes:

Step 1: Complete melting at 50–45 °C to eliminate all lower crystal forms

Step 2: Controlled cooling to ~27 °C for initiating pre-crystallization

Step 3: Reheating to ~31–32 °C to melt unstable forms while retaining βV crystals

This method is widely used in modern chocolate processing lines due to its reliability and scalability in industrial environments

Step-by-Step Tempering Process for Achieving βV Form in Chocolate Production

Role of SSHE in Stable βV Formation : Shear Rate and Holding Time

In continuous lines, Scraped Surface Heat Exchangers (SSHE) help control shear and thermal transfer. Two key parameters influence βV development:

High shear rate + low crystal size = promotes fine and uniform βV crystal formation

Residence time must be optimized to ensure complete nucleation and growth of stable βV forms

Research in ScienceDirect confirms that adjusting shear rate and residence time significantly impacts βV formation, with proper timing helping the system transition from Form IV to βV more effectively.

Using Inline Sensors and ML Algorithms to Predict βV Presence

Next-generation tempering systems integrate real-time sensors and machine learning models (ML) to monitor and predict βV formation based on:

SFC (Solid Fat Content): live tracking of fat crystal content to assess βV probability

Temperature + XRD data: combined with ML, enhances prediction of βV regions in the temper curve

These technologies allow automated temper control, enabling consistent crystal outcomes. Studies report up to 60% improvement in βV yield when using integrated SFC + ML systems.

To better understand cocoa butter and its impact on chocolate quality, read the article below :

What is cocoa butter ? Properties, uses, alternatives

- Related Articles

Technologies That Enhance βV Crystallizatio

What Are the Optimal SSHE Settings for Forming βV in Chocolate ?

In chocolate processing lines, Scraped Surface Heat Exchangers (SSHE) provide precise thermal and shear control for βV crystallization. Recommended SSHE parameters include:

Inlet temperature: 50–45 °C (complete melting)

Crystallization zone: Rapid cooling to 28–26 °C

Shear rate: 200–400 s⁻¹ for efficient crystal nucleation

Residence time: 30–90 seconds to ensure uniform βV growth

Additional Notes:

High thermal conductivity helps suppress unwanted polymorphs (e.g., Form IV or III)

Final chocolate mass exiting the SSHE should contain at least 3–5% stable βV crystals

Which phospholipids help the Beta5 Form form more quickly in chocolate?

Which Phospholipids Can Accelerate βV Formation in Chocolate?

Certain minor phospholipids like phosphatidylethanolamine (PE) and phosphatidylserine (PS) can act as natural nucleation promoters, enhancing the formation of βV crystals.

When added in trace amounts, they:

Lower the energy barrier for converting Form IV → Form V

Interact with TAGs like POP and POS to support βV templating

Improve lattice alignment, resulting in more uniform and stable crystals

These phospholipids are most effective when combined with optimized tempering temperature and shear rate settings.

🔗 Further details available in studies on phospholipid-induced pre-crystallization in chocolate.

Ultrasound-Assisted Crystallization in Chocolate Tempering

Ultrasound technology is increasingly used to enhance nucleation during tempering. Key effects include:

Promotes uniform micro-seeding of βV

Reduces tempering time and energy use

Can improve polymorph control in both pure cocoa butter and compound systems

Studies show that applying ultrasound at 20–40 kHz during tempering increases the proportion of Form V (βV) significantly.

XRD – The Most Accurate Method for βV Identification

Describes crystal structures based on d-spacing values

Differentiates βV from other forms like IV or VI

Requires specialized equipment and lab setting

Considered the gold standard for βV identification

Combine with DSC for more robust analysis

DSC – Thermal Profiling for βV Detection

Measures how DSC peaks shift during melting/crystallization

Differentiates metastable and stable forms

Suitable for inline QC or R&D environments

Can confirm presence of βV via thermal signature

DSC – Thermal Profiling for βV Detection

Measures how DSC peaks shift during melting/crystallization

Differentiates metastable and stable forms

Suitable for inline QC or R&D environments

Can confirm presence of βV via thermal signature

Analytical Tools for Evaluating Crystal Quality and Identifying the βV Form

These tools help determine the presence and quality of β5 Form in cocoa butter and chocolate. Each has its strengths and limitations :

📌 No single test is enough. Use a combination of XRD + DSC + physical testing for accurate βV validation in production.

Summary : What’s the Fastest and Most Reliable Way to Achieve the βV Form?

The most proven industrial approach combines:

Thermal profile: 45–50 °C → 27 °C → 31–32 °C

Seeding: 1–2% Seed Crystals

SFC monitoring (Solid Fat Content)

This combination reduces bloom risk and ensures at least 3–5% stable βV in the final product.