Innovation and Sustainability in Green Coffee Processing :

The Key to Quality and the Future of the Industry

Innovation and sustainability in green coffee processing have become the driving forces shaping the quality and future of the coffee industry.

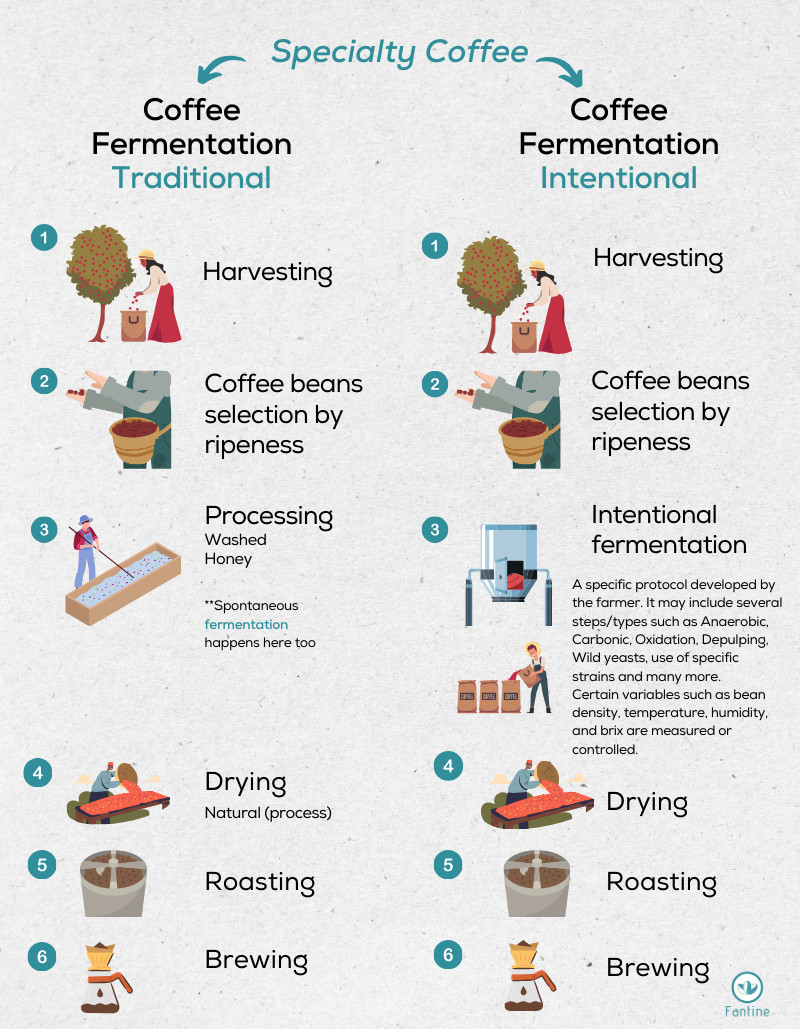

Processing today is not just a technical stage — it’s where flavor, aroma, body, and value of coffee are defined. From controlled fermentations and extended drying methods to enzymatic and microbial precision techniques, these innovations are transforming how beans express their origin and energy potential.

This synergy between innovation and sustainability doesn’t just enhance sensory experience; it creates a resilient framework for a more adaptive and climate-conscious coffee secto; one ready for a global future.

Modern Fermentation Methods for Green Coffee and Their Impact on Flavor

Anaerobic & Carbonic Fermentation in Coffee Processing :

Differences, Flavor Influence and Role in the Specialty Market

Anaerobic Fermentation

In this method, coffee cherries or pulped beans are fermented inside sealed stainless-steel tanks without oxygen exposure.

The absence of oxygen encourages the growth of specific microorganisms such as Lactobacillus and Saccharomyces, leading to complex aromatic compounds and higher acidity.

Studies in ScienceDirect and MDPI have shown that controlled anaerobic fermentation can produce distinctive fruity, floral, and wine-like profiles.

Carbonic Maceration

Inspired by winemaking, carbonic maceration involves fermenting whole coffee cherries in a closed tank filled with CO₂ instead of oxygen.

This process allows intracellular fermentation within the fruit, enhancing sweetness, roundness and delicate floral notes in the cup.

The result is a smooth, complex cup profile that’s gaining strong attention in the specialty coffee market.

Key Differences Between Anaerobic and Carbonic Fermentation

Environmental Conditions : Anaerobic involves extremely low oxygen; Carbonic uses a CO₂-rich atmosphere.

Execution : Anaerobic fermentation usually follows depulping; Carbonic uses whole, intact cherries.

Flavor & Aroma : Anaerobic enhances acidity and complexity; Carbonic delivers sweetness, roundness, and wine-like depth.

Microbial Activity : Both promote diverse, active microbial populations that shape unique coffee flavor profiles.

Both fermentation methods mark a new era of post-harvest innovation in coffee.

By controlling oxygen levels, temperature and microbial activity, producers craft distinct and high-value flavor experiences that define the future of specialty coffee.

How Do Anaerobic and Carbonic Fermentation Affect Coffee Flavor and Quality ?

Anaerobic and carbonic fermentation are among the most innovative post-harvest coffee processing techniques that directly influence the taste and quality of the final cup.

- They enhance fruity and aromatic notes, such as tones of berries, tropical fruits, and florals.

- They create greater complexity and a heavier mouthfeel compared to traditional washed or natural methods.

- They achieve better balance between sweetness and acidity, resulting in a smoother, more enjoyable cup.

- Because of these factors, they add flavor depth and market appeal, especially in specialty-grade coffees.

However, precise control of temperature and fermentation time is crucial. excessive or poorly managed fermentation may produce undesirable sourness or yeasty off-flavors similar to spoiled fruit or cake batter.

Semi-Carbonic Processing : Innovation for Smooth and Complex Coffee Flavors

Semi-carbonic fermentation bridges the gap between traditional and carbonic maceration methods.

In this approach, whole coffee cherries are fermented in partially sealed tanks where limited oxygen and CO₂ accumulate.

These conditions create a semi-anaerobic environment; not completely oxygen-free, yet not open fermentation either.

During processing, precise control of pH, time and temperature is essential.

When pH stabilizes around 4.0, fermentation slows, resulting in a balanced cup with mild acidity, fruity sweetness and delicate aroma complexity.

Advantages of the Semi-Carbonic Method :

Produces balanced, mellow and rounded flavors compared to fully carbonic maceration.

Reduces harsh acidity and undesirable fermentation notes.

Minimizes risk of microbial contamination and off-flavors.

Allows for clean fermentation under controlled oxygen levels without over-intense sensory impact.

Enhances consistency, cup quality and producer flexibility across harvests.

فرآوری قهوه به روش تلقیح مخمری و باکتریایی (Inoculated Fermentation)

Inoculated or bacterial fermentation is an advanced post-harvest approach where selected yeast and lactic acid bacteria strains are introduced to steer fermentation deliberately, rather than relying solely on natural environmental microbes.

Benefits of the Inoculated Method:

Enables precise flavor control and the formation of desirable aromatic compounds such as esters and organic acids, enhancing fruit and floral notes.

Stabilizes fermentation time, temperature, and pH, producing consistent and repeatable cup profiles.

Improves sensory quality while reducing the risk of unwanted sourness or excessive acidity caused by uncontrolled fermentation.

Encourages predictable outcomes, contributing to a more stable and distinctive sensory identity.

What’s the Difference Between Spontaneous and Inoculated Fermentation in Coffee ?

- Spontaneous Fermentation :

This process happens naturally, relying on the native microorganisms already present in the environment and on the coffee cherries themselves.

It can produce diverse and sometimes unpredictable flavor profiles ( from fruity and floral to earthy and winey ) but the outcome may vary from batch to batch due to less control and higher variability.

- Inoculated Fermentation :

In this controlled approach, producers intentionally introduce specific yeast or bacterial strains to guide the fermentation process.

This method enhances consistency, balance, and cleanliness in flavor while reducing the likelihood of undesirable or off-tasting notes.

The result is a cup that’s more stable, predictable, and precisely crafted toward desired flavor targets; for example, emphasizing tropical fruit, sweetness or clarity.

Thermo-Fermentation in Coffee Processing

In thermo-fermentation, one of the key principles is maintaining the temperature within a controlled range, ensuring that the activity of microbes and natural yeasts proceeds in a stable and predictable manner.

Temperature directly influences microbial metabolism, enzyme efficiency and the release of aromatic and flavor compounds during fermentation.

Advantages and Practical Techniques of Thermo-Fermentation

Advantages and Practical Techniques of Thermo-Fermentation

1. Flavor Stability and Quality Consistency

Fermentation conducted at controlled higher temperatures tends to produce coffees with balanced and enhanced flavor profiles, achieving higher SCA cupping scores with reduced variation between batches.

Temperature control also improves bean uniformity, maintaining physical qualities such as moisture content, density, and bean integrity.

2. Temperature and Time Profiling for Flavor Design

By adjusting both temperature and fermentation duration, producers can craft specific flavor outcomes and increase sensory diversity:

At lower temperatures (≈15°C), microbial activity slows down, resulting in gentler acidity and smoother flavors.

At higher temperatures (≈30°C), enzymatic reactions intensify, leading to stronger fruitiness, bolder body, and deeper complexity.

3. Chemical Parameter Control

Precise thermal regulation helps control lactic acid production, sugar conversion, and pH balance, all of which define sweetness, brightness, and the overall sensory harmony of the cup.

4. Continuous pH and Glucose Monitoring

Monitoring glucose levels and pH changes throughout the process provides the best indicators of fermentation progress and completion, helping ensure consistent, high-quality results.

Infused / Enhanced Coffee Processing

In coffee processing, microbial fermentation is one of the most crucial stages that shapes the production of aromatic compounds and organic acids.

In infused (enhanced) processing, external substances ( such as orange peel, cacao pulp, spices, or even other ferment liquids ) are intentionally added to the fermentation tank to influence the flavor outcome.

These additives can transfer their chemical compounds directly into the coffee beans (via extraction mechanisms) or alter the microbial community and metabolic pathways, steering the fermentation toward entirely new sensory profiles.

This innovative approach has opened doors to novel coffee flavor expressions and created a space for creative, experimental, and sensory-driven producers in the specialty sector.

Why It’s Controversial

While infused processing has produced some truly exciting and unique cup experiences, it remains a debated topic in the coffee world.

Some see it as a creative innovation, capable of adding new depth, story, and appeal to the market.

Others argue that it may blur the line between authentic and artificially enhanced coffee, especially when natural integrity and transparency are key values in specialty production.

Cold Plasma Processing :

Cold Plasma Processing

Plasma is the fourth state of matter, consisting of charged gas particles.

When produced at low temperatures, it’s called cold plasma.

One key advantage of this method is that it can be applied without heat, allowing microbial modification on coffee surfaces without damaging cell structures.

Cold plasma can alter bacterial and yeast communities and modify chemical compounds responsible for flavor and aroma.

Impact on Coffee Flavor:

Helps preserve aroma and enhance sensory quality.

Reduces microbial contamination, mold, and spoilage risk.

Increases bean safety and shelf-life while keeping natural flavors intact.

Advantages of Cold Plasma Processing:

Maintains original taste, aroma, and color due to low-temperature application.

Enables clean surface decontamination without extra chemicals.

Prevents over-fermentation and unwanted off-flavors.

Enzymatic Processing (Using Commercial Enzymes)

Smart use of enzymes ( through accurate type selection, dosage, duration, and pH control ) is one of the most advanced approaches to improving coffee flavor and stability.

Pectinase enzymes break down the mucilage layer surrounding coffee beans, improving fermentation efficiency and drying performance.

Other enzymes such as cellulase, protease, and amylase assist in releasing complex sugars and aroma precursors, boosting sweetness and clarity.

Benefits of Enzymatic Processing:

Reduces dirty cup or earthy defects caused by incomplete fermentation.

Produces cleaner, fruitier cups with vivid acidity and balanced sweetness.

Increases flavor clarity and consistency without over-fermenting.

Enhances pH stability and process predictability, improving overall quality.

Emerging Technologies for Microbial and Enzymatic Control in Coffee Processing :

Cold plasma and enzymatic processing are two cutting-edge technologies shaping the next era of coffee fermentation; merging precision microbiology with sensory craftsmanship to deliver cleaner, safer and more complex flavor experiences.

Eco-Friendly / Low-Water Coffee Processing

Eco-friendly or low-water coffee processing refers to modern methods that minimize water usage while reducing environmental impact and preserving or even improving cup quality.

Eco-Pulper Technology

Eco-pulper machines are specially designed systems that use significantly less water during the depulping stage; the process of separating the coffee pulp and mucilage from the beans.

In some models, the system works under pressure, reducing the need for continuous water flow.

Advantages :

-

Considerable reduction in water consumption and waste generation.

-

Cleaner operation and easier wastewater management during processing.

Wastewater and Pulp Management in Coffee Processing

One of the most important eco-technologies in coffee processing is the use of Deslim systems or biological filtration methods that help treat, recycle, or neutralize wastewater from coffee pulping stations.

These systems effectively reduce water pollution indicators such as COD (Chemical Oxygen Demand) and BOD (Biochemical Oxygen Demand), improving both water quality and environmental sustainability in local communities.

The Role of Eco Processing in Coffee Sustainability

-

Reducing pressure on freshwater resources and protecting surrounding ecosystems.

-

Lowering carbon footprint through reduced wastewater emissions and methane release.

-

Improving local economic resilience by cutting operational costs and maintaining long-term coffee quality.

-

Increasing the value of specialty coffee through environmental certifications and traceable, sustainable production.

Advanced Innovations in Coffee Drying and Moisture Management

One of the key innovations in modern coffee processing is the use of hybrid drying systems, which combine solar energy (solar drying) with mechanical airflow systems (mechanical drying) to achieve efficient, controlled, and sustainable drying.

Hybrid Coffee Drying: Integrating Solar and Mechanical Energy

Hybrid drying combines natural solar heat during the day with mechanical airflow or fan systems during the night or under humid conditions.

This combination ensures stable drying cycles and maintains consistent quality under variable weather conditions.

Advantages of Hybrid Drying Systems :

Reduced drying risk: Continuous air circulation prevents mold growth and over-fermentation, even when sunlight is limited.

Better energy efficiency: Utilizes renewable solar power alongside controlled mechanical drying, lowering energy costs and carbon footprint.

Improved cup quality: Beans retain more aroma, color, and uniformity, resulting in higher sensory consistency.

Extended shelf life: Balanced moisture content and precise temperature management protect bean structure and long-term storage stability.

Studies have shown that hybrid solar-mechanical systems can reduce total drying time by up to 70%, improving processing efficiency while ensuring better control over flavor and quality.

How Do Low-Water Processing Methods Support Coffee Industry Sustainability ?

Low-water processing methods can significantly reduce water consumption and minimize wastewater pollution during coffee production.

By limiting the pressure on freshwater resources ( especially in drought-prone coffee-growing regions ) these systems help conserve the environment while maintaining bean quality.

Technologies such as Deslim filtration further reduce contamination levels and enable cleaner processing cycles.

When combined with efficient equipment like eco-pulpers, these methods support both environmental sustainability and the livelihoods of smallholder coffee farmers.

Conclusion : The Future of Coffee ; Between Innovation, Authenticity and Sustainability

Innovative coffee processing methods ( from eco-friendly and low-water systems to semi-carbonic and infused approaches ) are opening vast opportunities to enhance flavor diversity and cup quality across the specialty sector.

Advantages :

Creation of new flavor profiles and value-added products.

Reduction in water consumption and improved economic efficiency for producers.

Challenges :

Managing flavor risks and maintaining balance to avoid unwanted notes.

Preserving authenticity and ensuring compliance with specialty coffee standards.

Ultimately, the future of coffee lies in maintaining a balance between authenticity, sustainability, and quality — a harmony that benefits both producers and the planet.