The Importance of Cocoa Butter in Chocolate Structure, Performance and Overall Quality

Cocoa butter is the essential fat foundation in chocolate formulations, defining snap, melt behavior, flow properties, gloss, texture and mouthfeel.

In chocolate, thermal behavior and structural stability depend heavily on the triacylglycerol (TAG) composition of cocoa butter and the way these TAGs crystallize. The functional quality of cocoa butter mainly comes from its dominant TAG profile ( POP, POS and SOS ) which determines melting behavior, hardness, bloom resistance and tempering performance.

Although minor components such as DG (diglycerides) and FFA (free fatty acids) are present at low levels, they significantly influence crystallization behavior, melting characteristics and the overall stability of chocolate.

To better understand cocoa butter and its role in chocolate quality, read the article below :

What Is Cocoa Butter ? Properties, Applications and Industrial Replacements

- Related Articles

رنسیدیتی هیدرولیتیک کره کاکائو و نقش FFA در افت کیفیت

Excess FFA disrupts crystallization, lowers SFC and significantly increases the risk of fat bloom, negatively affecting melting behavior and sensory attributes.

Diagnostic Methods

FFA measurement (ISO 660)

Moisture measurement

GC–MS analysis of short-chain fatty acids and lipolysis markers

Corrective Actions to Reduce FFA

Control temperature and fermentation time

Dry beans to ≤7% moisture

Targeted deodorization for reducing FFA

Avoiding moisture migration during storage

Preventing mould contamination during drying

Scientific Note (Source-based Insight)

Oxidative Rancidity in Cocoa Butter (Oxidative Rancidity / PV–AV–TOTOX)

Oxidative rancidity is a major degradation pathway in cocoa butter, driven by the formation and breakdown of lipid hydroperoxides (LOOH) into volatile compounds responsible for sharp, rancid or fatty–oxidized notes.

These oxidative products accumulate during storage, directly reducing the sensory quality and long-term stability of chocolate.

The process is entirely chemical: exposure of cocoa butter to oxygen, heat, light and trace metals accelerates oxidation and increases the formation of off-flavour aldehydes.

The severity of oxidative rancidity depends on the FFA level, processing conditions and storage temperature.

Diagnostic Markers

PV (Peroxide Value)

p-AV (para-Anisidine Value)

TOTOX Index

GC–MS profiling of key aldehydes, including:

Hexanal

Heptanal

Nonanal

Corrective Actions

Use of antioxidants (natural or process-derived)

Improved refining and deodorization

Light- and oxygen-resistant packaging

Reducing contact with catalytic metals

Key Challenges: Cocoa Butter Rancidity, Off-Flavour Development, Crystal Instability and Shelf-Life Reduction

The quality and stability of cocoa butter are influenced by a complex set of chemical, enzymatic, thermal and physical reactions that occur throughout processing, storage, and distribution.

These reactions alter the triacylglycerol (TAG) structure, crystal forms, and the composition of the fat phase; ultimately affecting melt behavior, gloss, texture and the sensory quality of chocolate.

The most critical pathways include hydrolytic rancidity, oxidative rancidity, polymorphic transitions and lipid migration. Each pathway can produce off-flavours, increase the risk of fat bloom and disrupt crystal stability. These mechanisms directly impact the long-term durability and thermal stability of chocolate.

![{"type":"elementor","siteurl":"https://sosa-conf.com/wp-json/","elements":[{"id":"d24482b","elType":"widget","isInner":false,"isLocked":false,"settings":{"content_width":"full","title":"ترکیبات مولد Off-Flavour در کرهٔ کاکائو","align_mobile":"center","typography_typography":"custom","typography_font_family":"IranSans","typography_font_size_tablet":{"unit":"px","size":20,"sizes":[]},"typography_font_weight":"700","__globals__":{"title_color":"globals/colors?id=text"},"scroll_y":-80,"typography_font_size":{"unit":"px","size":16,"sizes":[]},"typography_font_size_mobile":{"unit":"px","size":30,"sizes":[]},"typography_line_height_mobile":{"unit":"em","size":1.5,"sizes":[]},"_padding_mobile":{"unit":"px","top":"0","right":"0","bottom":"0","left":"0","isLinked":false},"_flex_align_self_mobile":"center","element_parallax":"","scroll_x":0,"scroll_z":0,"scroll_smoothness":"30","wd_animation":"","wd_animation_duration":"normal","wd_animation_delay":100,"_background_gradient_position_tablet":"center center","_background_gradient_position_mobile":"center center","_background_hover_gradient_position_tablet":"center center","_background_hover_gradient_position_mobile":"center center","eael_tooltip_section_content":"I am a tooltip","eael_ext_content_protection_password_placeholder":"Enter Password","eael_ext_content_protection_password_submit_btn_txt":"Submit","eael_ext_content_protection_password_incorrect_message":"Password does not match.","eael_cl_logics":[{"_id":"8f7fe9f","logic_type":"login_status","dynamic_field":"","logic_operator_dynamic":"between","login_status_operand":"logged_in","user_and_role":"","logic_operator_between":"between","dynamic_operand":"","user_role_operand_multi":[],"user_operand":"","post_type_operand":"","post_operand":"","post_operand_post":"","post_operand_page":"","post_operand_e-landing-page":"","post_operand_benchmark":"","post_operand_trend":"","post_operand_docs":"","post_operand_news":"","post_operand_sosa_product":"","browser_operand":"chrome","date_time_logic":"equal","single_date":"","from_date":"","to_date":"","recurring_day_logic":"between","recurring_days_all":"","recurring_days":["sun"],"recurring_days_duration_from":"","recurring_days_duration_to":"","from_time":"","to_time":"","query_key":"","query_value":""}],"pafe_custom_media_query_breakpoints_list":[],"pafe_conditional_visibility_time_repeater":[],"pafe_conditional_visibility_by_backend_list":[],"pafe_absolute_positioning_top":"auto","pafe_absolute_positioning_right":"auto","pafe_absolute_positioning_bottom":"auto","pafe_absolute_positioning_left":"auto","pafe_toggle_content_speed":400,"pafe_toggle_content_easing":"swing","_css_classes":"sosa-title","typography_line_height":{"unit":"rem","size":1.5,"sizes":[]},"typography_line_height_tablet":{"unit":"em","size":1.5,"sizes":[]},"_background_color_stop_tablet":{"unit":"%","size":"","sizes":[]},"_background_color_stop_mobile":{"unit":"%","size":"","sizes":[]},"_background_color_b_stop_tablet":{"unit":"%","size":"","sizes":[]},"_background_color_b_stop_mobile":{"unit":"%","size":"","sizes":[]},"_background_gradient_angle_tablet":{"unit":"deg","size":"","sizes":[]},"_background_gradient_angle_mobile":{"unit":"deg","size":"","sizes":[]},"_background_hover_color_stop_tablet":{"unit":"%","size":"","sizes":[]},"_background_hover_color_stop_mobile":{"unit":"%","size":"","sizes":[]},"_background_hover_color_b_stop_tablet":{"unit":"%","size":"","sizes":[]},"_background_hover_color_b_stop_mobile":{"unit":"%","size":"","sizes":[]},"_background_hover_gradient_angle_tablet":{"unit":"deg","size":"","sizes":[]},"_background_hover_gradient_angle_mobile":{"unit":"deg","size":"","sizes":[]},"header_size":"h3","eael_image_masking_custom_clip_path":"clip-path: polygon(50% 0%, 80% 10%, 100% 35%, 100% 70%, 80% 90%, 50% 100%, 20% 90%, 0% 70%, 0% 35%, 20% 10%);","eael_image_masking_custom_clip_path_hover":"clip-path: polygon(50% 0%, 80% 10%, 100% 35%, 100% 70%, 80% 90%, 50% 100%, 20% 90%, 0% 70%, 0% 35%, 20% 10%);","eael_vto_writing_gradient_color_repeater":[{"eael_vto_writing_gradient_color":"#7C62FF","eael_vto_writing_gradient_color_location":{"unit":"%","size":50},"_id":"25d24b2"},{"eael_vto_writing_gradient_color":"#FF6464","eael_vto_writing_gradient_color_location":{"unit":"%","size":90},"_id":"69ff6ea"}],"link":{"url":"","is_external":"","nofollow":"","custom_attributes":""},"size":"default","align":"","align_tablet":"","typography_text_transform":"","typography_font_style":"","typography_text_decoration":"","typography_letter_spacing":{"unit":"px","size":"","sizes":[]},"typography_letter_spacing_tablet":{"unit":"px","size":"","sizes":[]},"typography_letter_spacing_mobile":{"unit":"px","size":"","sizes":[]},"typography_word_spacing":{"unit":"px","size":"","sizes":[]},"typography_word_spacing_tablet":{"unit":"em","size":"","sizes":[]},"typography_word_spacing_mobile":{"unit":"em","size":"","sizes":[]},"text_stroke_text_stroke_type":"","text_stroke_text_stroke":{"unit":"px","size":"","sizes":[]},"text_stroke_text_stroke_tablet":{"unit":"px","size":"","sizes":[]},"text_stroke_text_stroke_mobile":{"unit":"px","size":"","sizes":[]},"text_stroke_stroke_color":"#000","text_shadow_text_shadow_type":"","text_shadow_text_shadow":{"horizontal":0,"vertical":0,"blur":10,"color":"rgba(0,0,0,0.3)"},"blend_mode":"","title_color":"","title_hover_color":"","title_hover_color_transition_duration":{"unit":"s","size":"","sizes":[]},"eael_vertical_text_orientation_switch":"","eael_vto_writing_mode":"vertical-lr","eael_vto_writing_mode_flip":"","eael_vto_writing_height":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_height_tablet":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_height_mobile":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_text_orientation":"","eael_vto_writing_letter_spacing":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_letter_spacing_tablet":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_letter_spacing_mobile":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_word_spacing":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_word_spacing_tablet":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_word_spacing_mobile":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_text_indent":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_text_indent_tablet":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_text_indent_mobile":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_line_height":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_line_height_tablet":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_line_height_mobile":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_styling_type":"normal","eael_vto_writing_styling_background_background":"","eael_vto_writing_styling_background_color":"","eael_vto_writing_styling_background_color_stop":{"unit":"%","size":0,"sizes":[]},"eael_vto_writing_styling_background_color_stop_tablet":{"unit":"%"},"eael_vto_writing_styling_background_color_stop_mobile":{"unit":"%"},"eael_vto_writing_styling_background_color_b":"#f2295b","eael_vto_writing_styling_background_color_b_stop":{"unit":"%","size":100,"sizes":[]},"eael_vto_writing_styling_background_color_b_stop_tablet":{"unit":"%"},"eael_vto_writing_styling_background_color_b_stop_mobile":{"unit":"%"},"eael_vto_writing_styling_background_gradient_type":"linear","eael_vto_writing_styling_background_gradient_angle":{"unit":"deg","size":180,"sizes":[]},"eael_vto_writing_styling_background_gradient_angle_tablet":{"unit":"deg"},"eael_vto_writing_styling_background_gradient_angle_mobile":{"unit":"deg"},"eael_vto_writing_styling_background_gradient_position":"center center","eael_vto_writing_styling_background_gradient_position_tablet":"","eael_vto_writing_styling_background_gradient_position_mobile":"","eael_vto_writing_styling_background_image":{"url":"","id":"","size":""},"eael_vto_writing_styling_background_image_tablet":{"url":"","id":"","size":""},"eael_vto_writing_styling_background_image_mobile":{"url":"","id":"","size":""},"eael_vto_writing_styling_background_position":"","eael_vto_writing_styling_background_position_tablet":"","eael_vto_writing_styling_background_position_mobile":"","eael_vto_writing_styling_background_xpos":{"unit":"px","size":0,"sizes":[]},"eael_vto_writing_styling_background_xpos_tablet":{"unit":"px","size":0,"sizes":[]},"eael_vto_writing_styling_background_xpos_mobile":{"unit":"px","size":0,"sizes":[]},"eael_vto_writing_styling_background_ypos":{"unit":"px","size":0,"sizes":[]},"eael_vto_writing_styling_background_ypos_tablet":{"unit":"px","size":0,"sizes":[]},"eael_vto_writing_styling_background_ypos_mobile":{"unit":"px","size":0,"sizes":[]},"eael_vto_writing_styling_background_attachment":"","eael_vto_writing_styling_background_repeat":"","eael_vto_writing_styling_background_repeat_tablet":"","eael_vto_writing_styling_background_repeat_mobile":"","eael_vto_writing_styling_background_size":"","eael_vto_writing_styling_background_size_tablet":"","eael_vto_writing_styling_background_size_mobile":"","eael_vto_writing_styling_background_bg_width":{"unit":"%","size":100,"sizes":[]},"eael_vto_writing_styling_background_bg_width_tablet":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_styling_background_bg_width_mobile":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_styling_background_video_link":"","eael_vto_writing_styling_background_video_start":"","eael_vto_writing_styling_background_video_end":"","eael_vto_writing_styling_background_play_once":"","eael_vto_writing_styling_background_play_on_mobile":"","eael_vto_writing_styling_background_privacy_mode":"","eael_vto_writing_styling_background_video_fallback":{"url":"","id":"","size":""},"eael_vto_writing_styling_background_slideshow_gallery":[],"eael_vto_writing_styling_background_slideshow_loop":"yes","eael_vto_writing_styling_background_slideshow_slide_duration":5000,"eael_vto_writing_styling_background_slideshow_slide_transition":"fade","eael_vto_writing_styling_background_slideshow_transition_duration":500,"eael_vto_writing_styling_background_slideshow_background_size":"","eael_vto_writing_styling_background_slideshow_background_size_tablet":"","eael_vto_writing_styling_background_slideshow_background_size_mobile":"","eael_vto_writing_styling_background_slideshow_background_position":"","eael_vto_writing_styling_background_slideshow_background_position_tablet":"","eael_vto_writing_styling_background_slideshow_background_position_mobile":"","eael_vto_writing_styling_background_slideshow_lazyload":"","eael_vto_writing_styling_background_slideshow_ken_burns":"","eael_vto_writing_styling_background_slideshow_ken_burns_zoom_direction":"in","eael_vto_writing_styling_text_clip":"yes","eael_vto_writing_styling_text_animation_bg":"","eael_vto_writing_text_animation_control":"vertical","eael_vto_writing_gradient_color_angle":{"unit":"deg","size":95,"sizes":[]},"eael_vto_writing_gradient_color_angle_tablet":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_gradient_color_angle_mobile":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_styling_text_animation":"","eael_vto_writing_gradient_color_angle_vertical":{"unit":"deg","size":2,"sizes":[]},"eael_vto_writing_gradient_color_angle_vertical_tablet":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_gradient_color_angle_vertical_mobile":{"unit":"px","size":"","sizes":[]},"eael_vto_writing_styling_text_animation_vertical":"","_title":"","_margin":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_margin_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_margin_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_padding":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_padding_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_element_width":"","_element_width_tablet":"","_element_width_mobile":"","_element_custom_width":{"unit":"%","size":"","sizes":[]},"_element_custom_width_tablet":{"unit":"px","size":"","sizes":[]},"_element_custom_width_mobile":{"unit":"px","size":"","sizes":[]},"_grid_column":"","_grid_column_tablet":"","_grid_column_mobile":"","_grid_column_custom":"","_grid_column_custom_tablet":"","_grid_column_custom_mobile":"","_grid_row":"","_grid_row_tablet":"","_grid_row_mobile":"","_grid_row_custom":"","_grid_row_custom_tablet":"","_grid_row_custom_mobile":"","_flex_align_self":"","_flex_align_self_tablet":"","_flex_order":"","_flex_order_tablet":"","_flex_order_mobile":"","_flex_order_custom":"","_flex_order_custom_tablet":"","_flex_order_custom_mobile":"","_flex_size":"","_flex_size_tablet":"","_flex_size_mobile":"","_flex_grow":1,"_flex_grow_tablet":"","_flex_grow_mobile":"","_flex_shrink":1,"_flex_shrink_tablet":"","_flex_shrink_mobile":"","_element_vertical_align":"","_element_vertical_align_tablet":"","_element_vertical_align_mobile":"","_position":"","_offset_orientation_h":"start","_offset_x":{"unit":"px","size":0,"sizes":[]},"_offset_x_tablet":{"unit":"px","size":"","sizes":[]},"_offset_x_mobile":{"unit":"px","size":"","sizes":[]},"_offset_x_end":{"unit":"px","size":0,"sizes":[]},"_offset_x_end_tablet":{"unit":"px","size":"","sizes":[]},"_offset_x_end_mobile":{"unit":"px","size":"","sizes":[]},"_offset_orientation_v":"start","_offset_y":{"unit":"px","size":0,"sizes":[]},"_offset_y_tablet":{"unit":"px","size":"","sizes":[]},"_offset_y_mobile":{"unit":"px","size":"","sizes":[]},"_offset_y_end":{"unit":"px","size":0,"sizes":[]},"_offset_y_end_tablet":{"unit":"px","size":"","sizes":[]},"_offset_y_end_mobile":{"unit":"px","size":"","sizes":[]},"_z_index":"","_z_index_tablet":"","_z_index_mobile":"","_element_id":"","e_display_conditions":"","_element_cache":"","eael_wrapper_link_switch":"","eael_wrapper_link":{"url":"","is_external":"","nofollow":"","custom_attributes":""},"eael_wrapper_link_disable_traditional":"","eael_hover_effect_switch":"","eael_hover_effect_enable_live_changes":"","eael_hover_effect_opacity_popover":"","eael_hover_effect_opacity":{"unit":"px","size":0.8,"sizes":[]},"eael_hover_effect_filter_popover":"","eael_hover_effect_blur_is_on":"","eael_hover_effect_blur":{"unit":"px","size":1,"sizes":[]},"eael_hover_effect_contrast_is_on":"","eael_hover_effect_contrast":{"unit":"px","size":80,"sizes":[]},"eael_hover_effect_grayscale_is_on":"","eael_hover_effect_grayscal":{"unit":"px","size":40,"sizes":[]},"eael_hover_effect_invert_is_on":"","eael_hover_effect_invert":{"unit":"px","size":70,"sizes":[]},"eael_hover_effect_saturate_is_on":"","eael_hover_effect_saturate":{"unit":"px","size":50,"sizes":[]},"eael_hover_effect_sepia_is_on":"","eael_hover_effect_sepia":{"unit":"px","size":50,"sizes":[]},"eael_hover_effect_offset_popover":"","eael_hover_effect_offset_left":{"unit":"px","size":5,"sizes":[]},"eael_hover_effect_offset_left_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_offset_left_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_offset_top":{"unit":"px","size":5,"sizes":[]},"eael_hover_effect_offset_top_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_offset_top_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_popover":"","eael_hover_effect_rotate_is_on":"","eael_hover_effect_transform_rotatex":{"unit":"px","size":0,"sizes":[]},"eael_hover_effect_transform_rotatex_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_rotatex_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_rotatey":{"unit":"px","size":0,"sizes":[]},"eael_hover_effect_transform_rotatey_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_rotatey_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_rotatez":{"unit":"px","size":5,"sizes":[]},"eael_hover_effect_transform_rotatez_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_rotatez_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_scale_is_on":"","eael_hover_effect_transform_scalex":{"unit":"px","size":0.9,"sizes":[]},"eael_hover_effect_transform_scalex_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_scalex_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_scaley":{"unit":"px","size":0.9,"sizes":[]},"eael_hover_effect_transform_scaley_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_scaley_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_skew_is_on":"","eael_hover_effect_transform_skewx":{"unit":"px","size":5,"sizes":[]},"eael_hover_effect_transform_skewx_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_skewx_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_skewy":{"unit":"px","size":5,"sizes":[]},"eael_hover_effect_transform_skewy_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_skewy_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_general_settings_duration":{"unit":"px","size":1000,"sizes":[]},"eael_hover_effect_general_settings_delay":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_general_settings_easing":"ease","eael_hover_effect_opacity_popover_hover":"","eael_hover_effect_opacity_hover":{"unit":"px","size":1,"sizes":[]},"eael_hover_effect_filter_hover_popover":"","eael_hover_effect_blur_hover_is_on":"","eael_hover_effect_blur_hover":{"unit":"px","size":0,"sizes":[]},"eael_hover_effect_contrast_hover_is_on":"","eael_hover_effect_contrast_hover":{"unit":"%","size":100,"sizes":[]},"eael_hover_effect_grayscale_hover_is_on":"","eael_hover_effect_grayscal_hover":{"unit":"%","size":0,"sizes":[]},"eael_hover_effect_invert_hover_is_on":"","eael_hover_effect_invert_hover":{"unit":"%","size":0,"sizes":[]},"eael_hover_effect_saturate_hover_is_on":"","eael_hover_effect_saturate_hover":{"unit":"%","size":100,"sizes":[]},"eael_hover_effect_sepia_hover_is_on":"","eael_hover_effect_sepia_hover":{"unit":"px","size":1,"sizes":[]},"eael_hover_effect_offset_hover_popover":"","eael_hover_effect_offset_hover_left":{"unit":"px","size":0,"sizes":[]},"eael_hover_effect_offset_hover_left_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_offset_hover_left_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_offset_hover_top":{"unit":"px","size":0,"sizes":[]},"eael_hover_effect_offset_hover_top_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_offset_hover_top_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_hover_popover":"","eael_hover_effect_rotate_hover_is_on":"","eael_hover_effect_transform_hover_rotatex":{"unit":"px","size":0,"sizes":[]},"eael_hover_effect_transform_hover_rotatex_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_hover_rotatex_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_hover_rotatey":{"unit":"px","size":0,"sizes":[]},"eael_hover_effect_transform_hover_rotatey_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_hover_rotatey_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_hover_rotatez":{"unit":"px","size":0,"sizes":[]},"eael_hover_effect_transform_hover_rotatez_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_hover_rotatez_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_scale_hover_is_on":"","eael_hover_effect_transform_hover_scalex":{"unit":"px","size":1,"sizes":[]},"eael_hover_effect_transform_hover_scalex_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_hover_scalex_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_hover_scaley":{"unit":"px","size":0,"sizes":[]},"eael_hover_effect_transform_hover_scaley_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_hover_scaley_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_skew_hover_is_on":"","eael_hover_effect_transform_hover_skewx":{"unit":"px","size":0,"sizes":[]},"eael_hover_effect_transform_hover_skewx_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_hover_skewx_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_hover_skewy":{"unit":"px","size":0,"sizes":[]},"eael_hover_effect_transform_hover_skewy_tablet":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_transform_hover_skewy_mobile":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_general_settings_hover_duration":{"unit":"px","size":1000,"sizes":[]},"eael_hover_effect_general_settings_hover_delay":{"unit":"px","size":"","sizes":[]},"eael_hover_effect_general_settings_hover_easing":"ease","eael_hover_effect_hover_tilt":"","eael_liquid_glass_effect_switch":"","eael_liquid_glass_effect":"effect1","eael_liquid_glass_effect_bg_color_effect1":"#FFFFFF1F","eael_liquid_glass_effect_bg_color_effect2":"#FFFFFF1F","eael_liquid_glass_effect_backdrop_filter_effect1":{"unit":"px","size":24,"sizes":[]},"eael_liquid_glass_effect_backdrop_filter_effect2":{"unit":"px","size":20,"sizes":[]},"eael_liquid_glass_effect_brightness_effect2":{"unit":"px","size":1,"sizes":[]},"eael_liquid_glass_border_distortion":"","eael_liquid_glass_border_radious_distortion":{"unit":"px","top":24,"right":24,"bottom":24,"left":24,"isLinked":true},"eael_liquid_glass_shadow_effect":"effect1","eael_liquid_glass_border_effect1_border":"solid","eael_liquid_glass_border_effect1_width":{"unit":"px","top":"1","right":"1","bottom":"1","left":"1","isLinked":false},"eael_liquid_glass_border_effect1_width_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_liquid_glass_border_effect1_width_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_liquid_glass_border_effect1_color":"#FFFFFF1F","eael_liquid_glass_border_effect2_border":"solid","eael_liquid_glass_border_effect2_width":{"unit":"px","top":"1","right":"1","bottom":"1","left":"1","isLinked":false},"eael_liquid_glass_border_effect2_width_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_liquid_glass_border_effect2_width_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_liquid_glass_border_effect2_color":"#FFFFFF1F","eael_liquid_glass_border_effect3_border":"solid","eael_liquid_glass_border_effect3_width":{"unit":"px","top":"1","right":"1","bottom":"1","left":"1","isLinked":false},"eael_liquid_glass_border_effect3_width_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_liquid_glass_border_effect3_width_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_liquid_glass_border_effect3_color":"#FFFFFF1F","eael_liquid_glass_border_effect4_border":"solid","eael_liquid_glass_border_effect4_width":{"unit":"px","top":"1","right":"1","bottom":"1","left":"1","isLinked":false},"eael_liquid_glass_border_effect4_width_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_liquid_glass_border_effect4_width_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_liquid_glass_border_effect4_color":"#AAAAAA1A","eael_liquid_glass_border_radius_effect1":{"unit":"px","top":24,"right":24,"bottom":24,"left":24,"isLinked":true},"eael_liquid_glass_border_radius_effect2":{"unit":"px","top":16,"right":16,"bottom":16,"left":16,"isLinked":true},"eael_liquid_glass_border_radius_effect3":{"unit":"px","top":8,"right":8,"bottom":8,"left":8,"isLinked":true},"eael_liquid_glass_border_radius_effect4":{"unit":"px","top":24,"right":24,"bottom":24,"left":24,"isLinked":true},"eael_liquid_glass_shadow_effect1_box_shadow_type":"yes","eael_liquid_glass_shadow_effect1_box_shadow":{"horizontal":0,"vertical":19,"blur":26,"spread":1,"color":"rgba(0,0,0,0.78)"},"eael_liquid_glass_shadow_effect1_box_shadow_position":" ","eael_liquid_glass_shadow_effect2_box_shadow_type":"yes","eael_liquid_glass_shadow_effect2_box_shadow":{"horizontal":0,"vertical":0,"blur":33,"spread":-2,"color":"#383C65"},"eael_liquid_glass_shadow_effect2_box_shadow_position":" ","eael_liquid_glass_shadow_effect3_box_shadow_type":"yes","eael_liquid_glass_shadow_effect3_box_shadow":{"horizontal":1,"vertical":1,"blur":10,"spread":5,"color":"rgba(255, 255, 255, 0.4)"},"eael_liquid_glass_shadow_effect3_box_shadow_position":" ","eael_liquid_glass_shadow_effect4_box_shadow_type":"yes","eael_liquid_glass_shadow_effect4_box_shadow":{"horizontal":0,"vertical":9,"blur":21,"spread":0,"color":"#00000040"},"eael_liquid_glass_shadow_effect4_box_shadow_position":" ","eael_enable_image_masking":"","eael_image_masking_type":"clip","eael_image_masking_clip_path":"bavel","eael_image_masking_enable_custom_clip_path":"","eael_image_masking_svg":"polygon","eael_image_masking_hover_effect":"","eael_image_masking_clip_path_hover":"bavel","eael_image_masking_enable_custom_clip_path_hover":"","eael_image_masking_svg_hover":"polygon","eael_image_masking_hover_selector":"","eael_image_masking_image_size":"contain","eael_image_masking_image_custom_size_custom":{"unit":"px","size":"","sizes":[]},"eael_image_masking_image_position":"center center","eael_image_masking_image_repeat":"no-repeat","eael_tooltip_section_enable":"","eael_tooltip_section_position":"top","eael_tooltip_auto_flip":"yes","eael_tooltip_section_animation":"scale","eael_tooltip_section_arrow":true,"eael_tooltip_section_arrow_type":"sharp","eael_tooltip_section_follow_cursor":"false","eael_tooltip_section_trigger":"mouseenter","eael_tooltip_section_duration":300,"eael_tooltip_section_delay":400,"eael_tooltip_section_size":"regular","eael_tooltip_section_typography_typography":"","eael_tooltip_section_typography_font_family":"","eael_tooltip_section_typography_font_size":{"unit":"px","size":"","sizes":[]},"eael_tooltip_section_typography_font_size_tablet":{"unit":"px","size":"","sizes":[]},"eael_tooltip_section_typography_font_size_mobile":{"unit":"px","size":"","sizes":[]},"eael_tooltip_section_typography_font_weight":"","eael_tooltip_section_typography_text_transform":"","eael_tooltip_section_typography_font_style":"","eael_tooltip_section_typography_text_decoration":"","eael_tooltip_section_typography_line_height":{"unit":"px","size":"","sizes":[]},"eael_tooltip_section_typography_line_height_tablet":{"unit":"em","size":"","sizes":[]},"eael_tooltip_section_typography_line_height_mobile":{"unit":"em","size":"","sizes":[]},"eael_tooltip_section_typography_letter_spacing":{"unit":"px","size":"","sizes":[]},"eael_tooltip_section_typography_letter_spacing_tablet":{"unit":"px","size":"","sizes":[]},"eael_tooltip_section_typography_letter_spacing_mobile":{"unit":"px","size":"","sizes":[]},"eael_tooltip_section_typography_word_spacing":{"unit":"px","size":"","sizes":[]},"eael_tooltip_section_typography_word_spacing_tablet":{"unit":"em","size":"","sizes":[]},"eael_tooltip_section_typography_word_spacing_mobile":{"unit":"em","size":"","sizes":[]},"eael_tooltip_section_background_color":"#000000","eael_tooltip_section_color":"#ffffff","eael_tooltip_section_border_color":"","eael_tooltip_section_border_radius":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_tooltip_section_distance":10,"eael_tooltip_section_padding":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_tooltip_section_box_shadow_box_shadow_type":"","eael_tooltip_section_box_shadow_box_shadow":{"horizontal":0,"vertical":0,"blur":10,"spread":0,"color":"rgba(0,0,0,0.5)"},"eael_tooltip_section_box_shadow_box_shadow_position":" ","eael_tooltip_section_width":{"unit":"px","size":"350","sizes":[]},"eael_ext_content_protection":"no","eael_ext_content_protection_type":"role","eael_ext_content_protection_role":"","eael_ext_content_protection_password":"","eael_ext_scroll_to_section":"yes","eael_content_protection_cookie":"no","eael_content_protection_cookie_expire_time":60,"eael_ext_content_protection_message_type":"text","eael_ext_content_protection_message_text":"You do not have permission to see this content.","eael_ext_content_protection_message_template":"","eael_ext_content_protection_message_text_color":"","eael_ext_content_protection_message_text_typography_typography":"","eael_ext_content_protection_message_text_typography_font_family":"","eael_ext_content_protection_message_text_typography_font_size":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_message_text_typography_font_size_tablet":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_message_text_typography_font_size_mobile":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_message_text_typography_font_weight":"","eael_ext_content_protection_message_text_typography_text_transform":"","eael_ext_content_protection_message_text_typography_font_style":"","eael_ext_content_protection_message_text_typography_text_decoration":"","eael_ext_content_protection_message_text_typography_line_height":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_message_text_typography_line_height_tablet":{"unit":"em","size":"","sizes":[]},"eael_ext_content_protection_message_text_typography_line_height_mobile":{"unit":"em","size":"","sizes":[]},"eael_ext_content_protection_message_text_typography_letter_spacing":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_message_text_typography_letter_spacing_tablet":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_message_text_typography_letter_spacing_mobile":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_message_text_typography_word_spacing":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_message_text_typography_word_spacing_tablet":{"unit":"em","size":"","sizes":[]},"eael_ext_content_protection_message_text_typography_word_spacing_mobile":{"unit":"em","size":"","sizes":[]},"eael_ext_content_protection_message_text_alignment":"left","eael_ext_content_protection_message_text_alignment_tablet":"","eael_ext_content_protection_message_text_alignment_mobile":"","eael_ext_content_protection_message_text_padding":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_message_text_padding_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_message_text_padding_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_error_message_text_color":"","eael_ext_content_protection_error_message_text_typography_typography":"","eael_ext_content_protection_error_message_text_typography_font_family":"","eael_ext_content_protection_error_message_text_typography_font_size":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_error_message_text_typography_font_size_tablet":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_error_message_text_typography_font_size_mobile":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_error_message_text_typography_font_weight":"","eael_ext_content_protection_error_message_text_typography_text_transform":"","eael_ext_content_protection_error_message_text_typography_font_style":"","eael_ext_content_protection_error_message_text_typography_text_decoration":"","eael_ext_content_protection_error_message_text_typography_line_height":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_error_message_text_typography_line_height_tablet":{"unit":"em","size":"","sizes":[]},"eael_ext_content_protection_error_message_text_typography_line_height_mobile":{"unit":"em","size":"","sizes":[]},"eael_ext_content_protection_error_message_text_typography_letter_spacing":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_error_message_text_typography_letter_spacing_tablet":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_error_message_text_typography_letter_spacing_mobile":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_error_message_text_typography_word_spacing":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_error_message_text_typography_word_spacing_tablet":{"unit":"em","size":"","sizes":[]},"eael_ext_content_protection_error_message_text_typography_word_spacing_mobile":{"unit":"em","size":"","sizes":[]},"eael_ext_content_protection_error_message_text_alignment":"left","eael_ext_content_protection_error_message_text_alignment_tablet":"","eael_ext_content_protection_error_message_text_alignment_mobile":"","eael_ext_content_protection_error_message_text_padding":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_error_message_text_padding_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_error_message_text_padding_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_input_width":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_input_alignment":"left","eael_ext_content_protection_input_alignment_tablet":"","eael_ext_content_protection_input_alignment_mobile":"","eael_ext_content_protection_password_input_padding":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_password_input_padding_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_password_input_padding_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_password_input_margin":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_password_input_margin_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_password_input_margin_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_input_border_radius":{"unit":"px","size":"","sizes":[]},"eael_ext_content_protection_password_input_color":"#333333","eael_ext_content_protection_password_input_bg_color":"#ffffff","eael_ext_content_protection_password_input_border_border":"","eael_ext_content_protection_password_input_border_width":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_password_input_border_width_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_password_input_border_width_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_password_input_border_color":"","eael_ext_content_protection_password_input_shadow_box_shadow_type":"","eael_ext_content_protection_password_input_shadow_box_shadow":{"horizontal":0,"vertical":0,"blur":10,"spread":0,"color":"rgba(0,0,0,0.5)"},"eael_ext_content_protection_password_input_shadow_box_shadow_position":" ","eael_ext_protected_content_password_input_hover_color":"#333333","eael_ext_protected_content_password_input_hover_bg_color":"#ffffff","eael_ext_protected_content_password_input_hover_border_border":"","eael_ext_protected_content_password_input_hover_border_width":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_protected_content_password_input_hover_border_width_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_protected_content_password_input_hover_border_width_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_protected_content_password_input_hover_border_color":"","eael_ext_protected_content_password_input_hover_shadow_box_shadow_type":"","eael_ext_protected_content_password_input_hover_shadow_box_shadow":{"horizontal":0,"vertical":0,"blur":10,"spread":0,"color":"rgba(0,0,0,0.5)"},"eael_ext_protected_content_password_input_hover_shadow_box_shadow_position":" ","eael_ext_content_protection_submit_button_color":"#ffffff","eael_ext_content_protection_submit_button_bg_color":"#333333","eael_ext_content_protection_submit_button_border_border":"","eael_ext_content_protection_submit_button_border_width":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_submit_button_border_width_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_submit_button_border_width_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_submit_button_border_color":"","eael_ext_content_protection_submit_button_box_shadow_box_shadow_type":"","eael_ext_content_protection_submit_button_box_shadow_box_shadow":{"horizontal":0,"vertical":0,"blur":10,"spread":0,"color":"rgba(0,0,0,0.5)"},"eael_ext_content_protection_submit_button_box_shadow_box_shadow_position":" ","eael_ext_content_protection_submit_button_hover_text_color":"#ffffff","eael_ext_content_protection_submit_button_hover_bg_color":"#333333","eael_ext_content_protection_submit_button_hover_border_border":"","eael_ext_content_protection_submit_button_hover_border_width":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_submit_button_hover_border_width_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_submit_button_hover_border_width_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"eael_ext_content_protection_submit_button_hover_border_color":"","eael_ext_content_protection_submit_button_hover_box_shadow_box_shadow_type":"","eael_ext_content_protection_submit_button_hover_box_shadow_box_shadow":{"horizontal":0,"vertical":0,"blur":10,"spread":0,"color":"rgba(0,0,0,0.5)"},"eael_ext_content_protection_submit_button_hover_box_shadow_box_shadow_position":" ","eael_cl_enable":"","eael_cl_visibility_action":"show","eael_cl_action_apply_if":"all","cpel_lv_enabled":"","cpel_lv_action":"show","cpel_lv_languages":[],"motion_fx_motion_fx_scrolling":"","motion_fx_translateY_effect":"","motion_fx_translateY_direction":"","motion_fx_translateY_speed":{"unit":"px","size":4,"sizes":[]},"motion_fx_translateY_affectedRange":{"unit":"%","size":"","sizes":{"start":0,"end":100}},"motion_fx_translateX_effect":"","motion_fx_translateX_direction":"","motion_fx_translateX_speed":{"unit":"px","size":4,"sizes":[]},"motion_fx_translateX_affectedRange":{"unit":"%","size":"","sizes":{"start":0,"end":100}},"motion_fx_opacity_effect":"","motion_fx_opacity_direction":"out-in","motion_fx_opacity_level":{"unit":"px","size":10,"sizes":[]},"motion_fx_opacity_range":{"unit":"%","size":"","sizes":{"start":20,"end":80}},"motion_fx_blur_effect":"","motion_fx_blur_direction":"out-in","motion_fx_blur_level":{"unit":"px","size":7,"sizes":[]},"motion_fx_blur_range":{"unit":"%","size":"","sizes":{"start":20,"end":80}},"motion_fx_rotateZ_effect":"","motion_fx_rotateZ_direction":"","motion_fx_rotateZ_speed":{"unit":"px","size":1,"sizes":[]},"motion_fx_rotateZ_affectedRange":{"unit":"%","size":"","sizes":{"start":0,"end":100}},"motion_fx_scale_effect":"","motion_fx_scale_direction":"out-in","motion_fx_scale_speed":{"unit":"px","size":4,"sizes":[]},"motion_fx_scale_range":{"unit":"%","size":"","sizes":{"start":20,"end":80}},"motion_fx_transform_origin_x":"center","motion_fx_transform_origin_y":"center","motion_fx_devices":["desktop","tablet","mobile"],"motion_fx_range":"","motion_fx_motion_fx_mouse":"","motion_fx_mouseTrack_effect":"","motion_fx_mouseTrack_direction":"","motion_fx_mouseTrack_speed":{"unit":"px","size":1,"sizes":[]},"motion_fx_tilt_effect":"","motion_fx_tilt_direction":"","motion_fx_tilt_speed":{"unit":"px","size":4,"sizes":[]},"handle_motion_fx_asset_loading":"","sticky":"","sticky_on":["desktop","tablet","mobile"],"sticky_offset":0,"sticky_offset_tablet":"","sticky_offset_mobile":"","sticky_effects_offset":0,"sticky_effects_offset_tablet":"","sticky_effects_offset_mobile":"","sticky_anchor_link_offset":0,"sticky_anchor_link_offset_tablet":"","sticky_anchor_link_offset_mobile":"","sticky_parent":"","_animation":"","_animation_tablet":"","_animation_mobile":"","animation_duration":"","_animation_delay":"","_transform_rotate_popover":"","_transform_rotateZ_effect":{"unit":"px","size":"","sizes":[]},"_transform_rotateZ_effect_tablet":{"unit":"deg","size":"","sizes":[]},"_transform_rotateZ_effect_mobile":{"unit":"deg","size":"","sizes":[]},"_transform_rotate_3d":"","_transform_rotateX_effect":{"unit":"px","size":"","sizes":[]},"_transform_rotateX_effect_tablet":{"unit":"deg","size":"","sizes":[]},"_transform_rotateX_effect_mobile":{"unit":"deg","size":"","sizes":[]},"_transform_rotateY_effect":{"unit":"px","size":"","sizes":[]},"_transform_rotateY_effect_tablet":{"unit":"deg","size":"","sizes":[]},"_transform_rotateY_effect_mobile":{"unit":"deg","size":"","sizes":[]},"_transform_perspective_effect":{"unit":"px","size":"","sizes":[]},"_transform_perspective_effect_tablet":{"unit":"px","size":"","sizes":[]},"_transform_perspective_effect_mobile":{"unit":"px","size":"","sizes":[]},"_transform_translate_popover":"","_transform_translateX_effect":{"unit":"px","size":"","sizes":[]},"_transform_translateX_effect_tablet":{"unit":"px","size":"","sizes":[]},"_transform_translateX_effect_mobile":{"unit":"px","size":"","sizes":[]},"_transform_translateY_effect":{"unit":"px","size":"","sizes":[]},"_transform_translateY_effect_tablet":{"unit":"px","size":"","sizes":[]},"_transform_translateY_effect_mobile":{"unit":"px","size":"","sizes":[]},"_transform_scale_popover":"","_transform_keep_proportions":"yes","_transform_scale_effect":{"unit":"px","size":"","sizes":[]},"_transform_scale_effect_tablet":{"unit":"px","size":"","sizes":[]},"_transform_scale_effect_mobile":{"unit":"px","size":"","sizes":[]},"_transform_scaleX_effect":{"unit":"px","size":"","sizes":[]},"_transform_scaleX_effect_tablet":{"unit":"px","size":"","sizes":[]},"_transform_scaleX_effect_mobile":{"unit":"px","size":"","sizes":[]},"_transform_scaleY_effect":{"unit":"px","size":"","sizes":[]},"_transform_scaleY_effect_tablet":{"unit":"px","size":"","sizes":[]},"_transform_scaleY_effect_mobile":{"unit":"px","size":"","sizes":[]},"_transform_skew_popover":"","_transform_skewX_effect":{"unit":"px","size":"","sizes":[]},"_transform_skewX_effect_tablet":{"unit":"deg","size":"","sizes":[]},"_transform_skewX_effect_mobile":{"unit":"deg","size":"","sizes":[]},"_transform_skewY_effect":{"unit":"px","size":"","sizes":[]},"_transform_skewY_effect_tablet":{"unit":"deg","size":"","sizes":[]},"_transform_skewY_effect_mobile":{"unit":"deg","size":"","sizes":[]},"_transform_flipX_effect":"","_transform_flipY_effect":"","_transform_rotate_popover_hover":"","_transform_rotateZ_effect_hover":{"unit":"px","size":"","sizes":[]},"_transform_rotateZ_effect_hover_tablet":{"unit":"deg","size":"","sizes":[]},"_transform_rotateZ_effect_hover_mobile":{"unit":"deg","size":"","sizes":[]},"_transform_rotate_3d_hover":"","_transform_rotateX_effect_hover":{"unit":"px","size":"","sizes":[]},"_transform_rotateX_effect_hover_tablet":{"unit":"deg","size":"","sizes":[]},"_transform_rotateX_effect_hover_mobile":{"unit":"deg","size":"","sizes":[]},"_transform_rotateY_effect_hover":{"unit":"px","size":"","sizes":[]},"_transform_rotateY_effect_hover_tablet":{"unit":"deg","size":"","sizes":[]},"_transform_rotateY_effect_hover_mobile":{"unit":"deg","size":"","sizes":[]},"_transform_perspective_effect_hover":{"unit":"px","size":"","sizes":[]},"_transform_perspective_effect_hover_tablet":{"unit":"px","size":"","sizes":[]},"_transform_perspective_effect_hover_mobile":{"unit":"px","size":"","sizes":[]},"_transform_translate_popover_hover":"","_transform_translateX_effect_hover":{"unit":"px","size":"","sizes":[]},"_transform_translateX_effect_hover_tablet":{"unit":"px","size":"","sizes":[]},"_transform_translateX_effect_hover_mobile":{"unit":"px","size":"","sizes":[]},"_transform_translateY_effect_hover":{"unit":"px","size":"","sizes":[]},"_transform_translateY_effect_hover_tablet":{"unit":"px","size":"","sizes":[]},"_transform_translateY_effect_hover_mobile":{"unit":"px","size":"","sizes":[]},"_transform_scale_popover_hover":"","_transform_keep_proportions_hover":"yes","_transform_scale_effect_hover":{"unit":"px","size":"","sizes":[]},"_transform_scale_effect_hover_tablet":{"unit":"px","size":"","sizes":[]},"_transform_scale_effect_hover_mobile":{"unit":"px","size":"","sizes":[]},"_transform_scaleX_effect_hover":{"unit":"px","size":"","sizes":[]},"_transform_scaleX_effect_hover_tablet":{"unit":"px","size":"","sizes":[]},"_transform_scaleX_effect_hover_mobile":{"unit":"px","size":"","sizes":[]},"_transform_scaleY_effect_hover":{"unit":"px","size":"","sizes":[]},"_transform_scaleY_effect_hover_tablet":{"unit":"px","size":"","sizes":[]},"_transform_scaleY_effect_hover_mobile":{"unit":"px","size":"","sizes":[]},"_transform_skew_popover_hover":"","_transform_skewX_effect_hover":{"unit":"px","size":"","sizes":[]},"_transform_skewX_effect_hover_tablet":{"unit":"deg","size":"","sizes":[]},"_transform_skewX_effect_hover_mobile":{"unit":"deg","size":"","sizes":[]},"_transform_skewY_effect_hover":{"unit":"px","size":"","sizes":[]},"_transform_skewY_effect_hover_tablet":{"unit":"deg","size":"","sizes":[]},"_transform_skewY_effect_hover_mobile":{"unit":"deg","size":"","sizes":[]},"_transform_flipX_effect_hover":"","_transform_flipY_effect_hover":"","_transform_transition_hover":{"unit":"px","size":"","sizes":[]},"motion_fx_transform_x_anchor_point":"","motion_fx_transform_x_anchor_point_tablet":"","motion_fx_transform_x_anchor_point_mobile":"","motion_fx_transform_y_anchor_point":"","motion_fx_transform_y_anchor_point_tablet":"","motion_fx_transform_y_anchor_point_mobile":"","_background_background":"","_background_color":"","_background_color_stop":{"unit":"%","size":0,"sizes":[]},"_background_color_b":"#f2295b","_background_color_b_stop":{"unit":"%","size":100,"sizes":[]},"_background_gradient_type":"linear","_background_gradient_angle":{"unit":"deg","size":180,"sizes":[]},"_background_gradient_position":"center center","_background_image":{"url":"","id":"","size":""},"_background_image_tablet":{"url":"","id":"","size":""},"_background_image_mobile":{"url":"","id":"","size":""},"_background_position":"","_background_position_tablet":"","_background_position_mobile":"","_background_xpos":{"unit":"px","size":0,"sizes":[]},"_background_xpos_tablet":{"unit":"px","size":0,"sizes":[]},"_background_xpos_mobile":{"unit":"px","size":0,"sizes":[]},"_background_ypos":{"unit":"px","size":0,"sizes":[]},"_background_ypos_tablet":{"unit":"px","size":0,"sizes":[]},"_background_ypos_mobile":{"unit":"px","size":0,"sizes":[]},"_background_attachment":"","_background_repeat":"","_background_repeat_tablet":"","_background_repeat_mobile":"","_background_size":"","_background_size_tablet":"","_background_size_mobile":"","_background_bg_width":{"unit":"%","size":100,"sizes":[]},"_background_bg_width_tablet":{"unit":"px","size":"","sizes":[]},"_background_bg_width_mobile":{"unit":"px","size":"","sizes":[]},"_background_video_link":"","_background_video_start":"","_background_video_end":"","_background_play_once":"","_background_play_on_mobile":"","_background_privacy_mode":"","_background_video_fallback":{"url":"","id":"","size":""},"_background_slideshow_gallery":[],"_background_slideshow_loop":"yes","_background_slideshow_slide_duration":5000,"_background_slideshow_slide_transition":"fade","_background_slideshow_transition_duration":500,"_background_slideshow_background_size":"","_background_slideshow_background_size_tablet":"","_background_slideshow_background_size_mobile":"","_background_slideshow_background_position":"","_background_slideshow_background_position_tablet":"","_background_slideshow_background_position_mobile":"","_background_slideshow_lazyload":"","_background_slideshow_ken_burns":"","_background_slideshow_ken_burns_zoom_direction":"in","_background_hover_background":"","_background_hover_color":"","_background_hover_color_stop":{"unit":"%","size":0,"sizes":[]},"_background_hover_color_b":"#f2295b","_background_hover_color_b_stop":{"unit":"%","size":100,"sizes":[]},"_background_hover_gradient_type":"linear","_background_hover_gradient_angle":{"unit":"deg","size":180,"sizes":[]},"_background_hover_gradient_position":"center center","_background_hover_image":{"url":"","id":"","size":""},"_background_hover_image_tablet":{"url":"","id":"","size":""},"_background_hover_image_mobile":{"url":"","id":"","size":""},"_background_hover_position":"","_background_hover_position_tablet":"","_background_hover_position_mobile":"","_background_hover_xpos":{"unit":"px","size":0,"sizes":[]},"_background_hover_xpos_tablet":{"unit":"px","size":0,"sizes":[]},"_background_hover_xpos_mobile":{"unit":"px","size":0,"sizes":[]},"_background_hover_ypos":{"unit":"px","size":0,"sizes":[]},"_background_hover_ypos_tablet":{"unit":"px","size":0,"sizes":[]},"_background_hover_ypos_mobile":{"unit":"px","size":0,"sizes":[]},"_background_hover_attachment":"","_background_hover_repeat":"","_background_hover_repeat_tablet":"","_background_hover_repeat_mobile":"","_background_hover_size":"","_background_hover_size_tablet":"","_background_hover_size_mobile":"","_background_hover_bg_width":{"unit":"%","size":100,"sizes":[]},"_background_hover_bg_width_tablet":{"unit":"px","size":"","sizes":[]},"_background_hover_bg_width_mobile":{"unit":"px","size":"","sizes":[]},"_background_hover_video_link":"","_background_hover_video_start":"","_background_hover_video_end":"","_background_hover_play_once":"","_background_hover_play_on_mobile":"","_background_hover_privacy_mode":"","_background_hover_video_fallback":{"url":"","id":"","size":""},"_background_hover_slideshow_gallery":[],"_background_hover_slideshow_loop":"yes","_background_hover_slideshow_slide_duration":5000,"_background_hover_slideshow_slide_transition":"fade","_background_hover_slideshow_transition_duration":500,"_background_hover_slideshow_background_size":"","_background_hover_slideshow_background_size_tablet":"","_background_hover_slideshow_background_size_mobile":"","_background_hover_slideshow_background_position":"","_background_hover_slideshow_background_position_tablet":"","_background_hover_slideshow_background_position_mobile":"","_background_hover_slideshow_lazyload":"","_background_hover_slideshow_ken_burns":"","_background_hover_slideshow_ken_burns_zoom_direction":"in","_background_hover_transition":{"unit":"px","size":"","sizes":[]},"_border_border":"","_border_width":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_border_width_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_border_width_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_border_color":"","_border_radius":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_border_radius_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_border_radius_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_box_shadow_box_shadow_type":"","_box_shadow_box_shadow":{"horizontal":0,"vertical":0,"blur":10,"spread":0,"color":"rgba(0,0,0,0.5)"},"_box_shadow_box_shadow_position":" ","_border_hover_border":"","_border_hover_width":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_border_hover_width_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_border_hover_width_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_border_hover_color":"","_border_radius_hover":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_border_radius_hover_tablet":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_border_radius_hover_mobile":{"unit":"px","top":"","right":"","bottom":"","left":"","isLinked":true},"_box_shadow_hover_box_shadow_type":"","_box_shadow_hover_box_shadow":{"horizontal":0,"vertical":0,"blur":10,"spread":0,"color":"rgba(0,0,0,0.5)"},"_box_shadow_hover_box_shadow_position":" ","_border_hover_transition":{"unit":"px","size":"","sizes":[]},"_mask_switch":"","_mask_shape":"circle","_mask_image":{"url":"","id":"","size":""},"_mask_image_tablet":{"url":"","id":"","size":""},"_mask_image_mobile":{"url":"","id":"","size":""},"_mask_size":"contain","_mask_size_tablet":"","_mask_size_mobile":"","_mask_size_scale":{"unit":"%","size":100,"sizes":[]},"_mask_size_scale_tablet":{"unit":"px","size":"","sizes":[]},"_mask_size_scale_mobile":{"unit":"px","size":"","sizes":[]},"_mask_position":"center center","_mask_position_tablet":"","_mask_position_mobile":"","_mask_position_x":{"unit":"%","size":0,"sizes":[]},"_mask_position_x_tablet":{"unit":"px","size":"","sizes":[]},"_mask_position_x_mobile":{"unit":"px","size":"","sizes":[]},"_mask_position_y":{"unit":"%","size":0,"sizes":[]},"_mask_position_y_tablet":{"unit":"px","size":"","sizes":[]},"_mask_position_y_mobile":{"unit":"px","size":"","sizes":[]},"_mask_repeat":"no-repeat","_mask_repeat_tablet":"","_mask_repeat_mobile":"","hide_desktop":"","hide_tablet":"","hide_mobile":"","_attributes":"","custom_css":""},"defaultEditSettings":{"defaultEditRoute":"content"},"elements":[],"widgetType":"heading","editSettings":{"defaultEditRoute":"content","panel":{"activeTab":"content","activeSection":"section_title"}},"htmlCache":""}]}](https://sosa-conf.com/wp-content/uploads/2025/11/Off-Flavor-Producing-Compounds-in-Cocoa-Butter-in-Fermentation.webp)

Impact of Farm Practices, Fermentation, Drying, and Processing on the Final Quality of Cocoa Butter

The quality of cocoa butter is directly shaped by farm-level practices, fermentation, drying, storage and subsequent factory operations.

Farm Stage :

At the farm level, factors such as pulp contamination, fruit spoilage, germination and prolonged post-harvest delays can activate endogenous and microbial lipases, leading to a significant increase in FFA levels.

During fermentation and drying Stage :

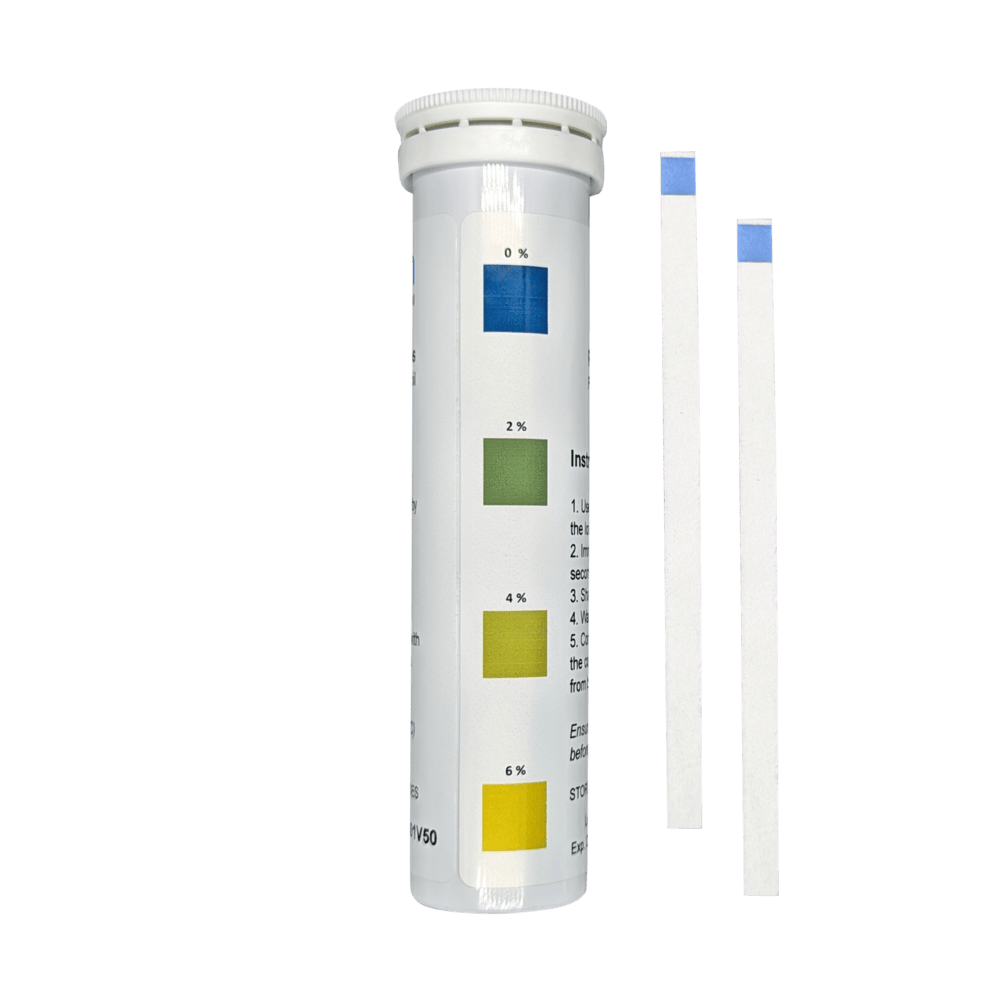

During fermentation and drying, temperature, humidity, and microbial activity determine the extent to which fat hydrolysis progresses. High moisture, insufficient drying, and smoke contamination are well-known risk factors that can lead to two distinct types of Off-Flavour:

1. Off-Flavour Resulting from Rancidity (FFA / Lipid Oxidation)

Increased TAG hydrolysis and elevated FFA

Sharp, rancid, waxy, or stale notes

Originates from oxidative instability of lipids, not from fermentation

2. Off-Flavour Resulting from Improper Fermentation or Drying

Acidic, alcoholic, estery, smoky or moldy notes

Caused by over-fermentation, under-fermentation, microbial contamination or smoke exposure

Originates from microbial metabolites; not lipid degradation

This distinction helps identify the underlying cause of Off-Flavour and guides corrective actions based on whether the source is lipid rancidity or fermentation-related deviations.

Storage Stage :

In storage, moisture migration and high humidity are major contributors to elevated FFA and lipid oxidation. Storing beans in non-breathable bags accelerates off-flavour formation and increases rancidity risks.

Processing (Factory) Stage :

During roasting and alkalization, temperature and oxygen exposure can accelerate oxidation and FFA formation if processing conditions are not controlled. Proper refining, pressing, and deodorization are essential for stabilizing cocoa butter and removing volatile rancid notes.

Cocoa Butter TAG Profile

The TAG profile of cocoa butter is dominated by three symmetrical triacylglycerols, which collectively form the characteristic melting behavior of cocoa butter:

POP (1,3-dipalmitoyl-2-oleoyl-glycerol)

POS (1-palmitoyl-3-stearoyl-2-oleoyl-glycerol)

SOS (1,3-distearoyl-2-oleoyl-glycerol)

Importance of POP–POS–SOS

They define the melting point, hardness, and crystallization behavior.

POS and SOS ratios determine snap, gloss, melting curve, and mouthfeel.

The balance among these TAGs is crucial for βV crystal formation, the desired form for high-quality chocolate.

Fatty Acid Profile :

Cocoa butter predominantly contains three major fatty acids:

Palmitic Acid (C16:0): ~24–27%

Stearic Acid (C18:0): ~33–36%

Oleic Acid (C18:1): ~33–38%

Nutritional Notes

Stearic acid is known for its neutral effect on LDL cholesterol.

Oleic acid is present at relatively high levels and contributes to hypocholesterolemic effects.

Palmitic acid serves as a stable, oxidation-resistant saturated fat supporting shelf-life.

Fatty Acid Profile and Key Triacylglycerols (TAGs) in Cocoa Butter (POP / POS / SOS)

Triacylglycerols (TAGs) are the primary structural lipids in cocoa butter. Each TAG consists of three fatty acids esterified to a glycerol backbone.

Measurable Parameters :

In chromatographic analysis, the POP/POS/SOS TAG ratios, the fatty acid composition and the SFC (Solid Fat Content) profile are key measurable parameters. These ratios directly influence melting point, crystallization behavior and overall fat performance.

Transition from βV to βVI and the Role of Temperature in Fat Bloom

During long-term storage or improper tempering, the βV form can transform into the more stable βVI polymorph.

This transformation leads to Fat Bloom, visible surface whitening, and loss of visual and textural quality.

The conversion from βV to βVI is temperature-dependent and accelerates under fluctuating or elevated storage temperatures.

High levels of minor lipids such as FFA, DG and MG also influence crystal behavior.

An increase in FFA above 1.7–2.1% significantly accelerates bloom formation and delays stable crystal development, reducing thermal stability and overall product quality.

Fat Bloom Diagnosis

DSC: Analysis of melting curves and polymorphic transitions

SFC: Solid fat content at different temperatures

XRD: Identification of βV and βVI crystal forms

Corrective Actions

Precise tempering to promote βV formation and prevent βV → βVI transition

Avoiding fat incompatibility (use of incompatible fats leading to mixed crystallization)

Stabilizing storage temperature and minimizing thermal cycling

Temperature instability accelerates the migration of oxidized or hydrolyzed lipids and increases the risk of Fat Bloom. Consistent temperature conditions slow down rancidity development and maintain fat stability.

Polymorphism and the Importance of the βV Crystal Form

Cocoa butter has six crystal forms, each with distinct melting behavior and stability. Among these forms, βV is the most stable and most desirable polymorph, with a melting point of approximately 32–34°C. This form provides optimal gloss, snap, melt-in-mouth performance and is essential for producing high-quality chocolate.

Industrial Importance

An increase in FFA above ~1.7–2.1% can disrupt the crystallization process, accelerate Bloom formation and reduce thermal and structural stability.

To achieve professional-level stability and ensure snap, gloss, and long-term quality in chocolate, read:

Comprehensive Guide to Achieving Cocoa Butter Form V (βV)

- Business partner

FFA ( Free Fatty Acids )

Free fatty acids are produced through the hydrolysis of triacylglycerols.

The allowable limit for cocoa butter is typically ≤ 1.75% w/w FFA (as oleic acid), which is considered a key quality criterion in many producing countries.

Sources of increase: over-fermentation, high moisture, mould activity, insufficient drying.

Impact on Quality

Disruption of βV crystal formation

Reduction of SFC

Delayed crystallization

Increased Fat Bloom risk

Analytical Method

ISO 660 — Acid Value / FFA titration

PV ( Peroxide Value )

Measures the amount of primary lipid hydroperoxides resulting from oxidation.

Unit: meq O₂/kg oil

Sensitivity: light, heat, oxygen, metal ions

Role

PV indicates the initiation of autoxidation; higher PV = stronger oxidative degradation.

Industrial Note

PV helps evaluate the influence of roasting, deodorization, and storage.

p-AV ( para-Anisidine Value )

Secondary oxidation index: measures aldehydic oxidation products absorbing at 350 nm.

Key Marker Compounds

Hexanal

Nonanal

2,4-Decadienal

Role

Complementary to PV; together they indicate advanced oxidation stages.

Sensory Impact

Associated with sharp, rancid, cardboard-like off-notes.

Quality and Lipid Stability Indices (FFA, PV, p-AV, TOTOX, SFC)

Triacylglycerols (TAGs) are the fundamental lipid structures in cocoa butter. Each TAG consists of three fatty acids attached to a glycerol backbone.

TOTOX ( Total Oxidation Index )

A combined index for primary and secondary oxidation products.

TOTOX = 2 × PV + p-AV

Applications

Comprehensive tool for shelf-life evaluation

Comparison of fats and production batches

Critical indicator for stability of sensitive fats such as cocoa butter

Industrial Importance

Higher TOTOX values correlate with increased oxidative rancidity and reduced flavour stability.

SFC ( Solid Fat Content )

The percentage of solid fat at different temperatures.

Role

Determines texture, melting profile, hardness, and mouthfeel of chocolate.

Standard Cocoa Butter SFC Profile (INSO 609)

21°C → ~76%

25°C → ~71%

31°C → ~42%

35°C → <2.5%

Influencing Factors

Tempering quality

TAG ratios

Presence of FFA, DG, MG

Analytical Methods

NMR (ISO 11487)

DSC (melting curve analysis)

SFC–Temperature Curve profiling (20–35°C)

Controlling Cocoa Butter Rancidity: The Key to Stability and Chocolate Quality

Preventing the increase of FFA and oxidative degradation requires precise control from the farm (harvest, fermentation, drying) to factory processing (roasting, deodorization, storage).

Rancidity directly affects flavour, melt profile, mouthfeel, and the visual stability of chocolate through oxidation, lipolysis, and polymorphic transitions.

To maintain long-term stability, manufacturers must rely on:

Controlled fermentation and drying

Proper storage and moisture control

Accurate tempering to ensure βV crystal formation

Routine testing of FFA, PV, p-AV, TOTOX, SFC

If you need cocoa butter that meets international standards and full stability criteria, contact our technical experts for professional sourcing and QC support.