Instant Cocoa Powder: Beyond Solubility , A Challenge Between Functional Consistency and Sensory Design

In the instant beverage industry , particularly in the development of instant cocoa powder—high solubility is just one part of the functional equation. The real challenge lies in achieving a balance between technical attributes such as dispersibility, compositional uniformity, and rapid dissolution, and a sensory experience that is consistently satisfying with every use.

At this intersection of functional performance and sensory perception, technologies like agglomeration have taken on a new level of importance. From precisely engineered particle structures to the targeted selection of raw materials and tight control over process parameters, these tools elevate instant cocoa powders from basic functional products into carefully crafted, repeatable consumption experiences.

Choosing the right cocoa powder defines the line between ordinary and premium.

Discover 5 key factors to create a formulation unmatched in quality, stability and taste.

- Related articles

The Role of Technology in Enhancing Sensory Performance

In the competitive world of instant products, rapid solubility alone is no longer sufficient. Sensory attributes (such as flavor, texture and aroma) alongside functional properties like flowability, dispersibility and shelf life, determine whether a consumer will repurchase a product. In this context, technology acts as the critical bridge between formulation design and the final user experience.

1. Technologies That Shape the Consumer Experience

Agglomeration : Improves dispersibility and prevents lump formation in liquids

Spray Drying : Enables precise control of residual moisture, particle size, and flavor uniformity

Encapsulation : Protects volatile flavor compounds and guards against oxidation

Granulation : Enhances dosage control and improves product stability during storage

2. Key Product Attributes Improved Through Processing Technologies

Cold solubility : Ensures quick dissolution even in low-temperature liquids

Mouthfeel and reconstituted texture : Delivers a smooth and consistent experience

Flavor and color uniformity: Maintains consistency with every serving

Dust reduction and better particle dispersion : Enhances handling and consumer usability

The sensory experience of an instant beverage goes far beyond flavor formulation, it’s a direct reflection of the technological decisions made throughout the production process. When process engineering and sensory design are aligned, the result is a product that delivers both functional excellence and lasting consumer satisfaction.

The Role of Agglomeration in Enhancing the Quality of Instant Beverage Powders

Technical Barriers in Conventional Powders :

Standard beverage powders, particularly “instant cocoa powder ” naturally exhibit physical characteristics that can compromise the overall consumer experience. The three primary challenges include:

Flowability:

The ability of a powder to move freely during packaging or dispensing. High bulk density and irregular particle shape often result in poor flow behavior.Dispersibility:

The powder’s ability to break apart and distribute evenly when introduced into a liquid. Fine or cohesive particles tend to form lumps or clusters, hindering uniform dispersion.Wettability:

The ease and speed with which powder particles become wetted by the liquid. In cocoa powder, surface fats significantly reduce wetting efficiency, delaying dissolution.

These three properties directly impact overall solubility, and their deficiencies can lead to common issues such as lump formation, sedimentation, or inconsistent flavor delivery.

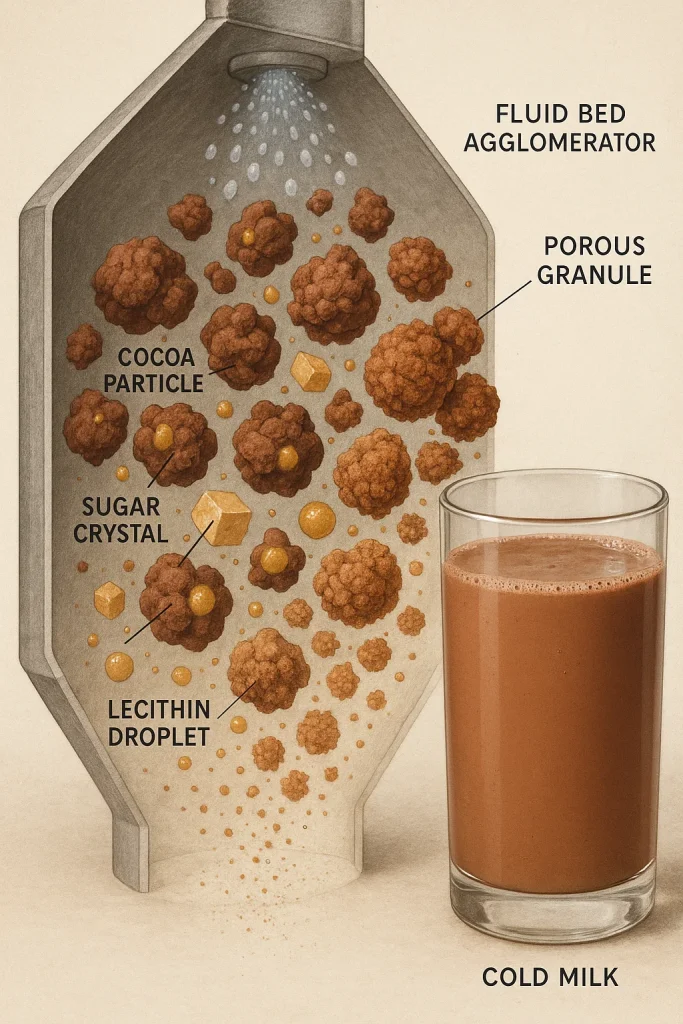

Scientific Mechanism of Particle Binding in Agglomeration :

Wetting Phase:

Cocoa and sugar particles are moistened using a liquid binder, often a solution of lecithin and water, to initiate surface activation.Liquid Bridge Formation:

The moisture creates temporary liquid bridges between particles, leading to the formation of loosely bound agglomerates through capillary and surface tension forces.Drying and Solid Bridge Formation:

Controlled drying removes excess moisture, transforming liquid bridges into stable solid bridges, resulting in a cohesive yet porous structure that maintains physical integrity.

Functional Benefits of Agglomeration on Final Product Quality :

Enhanced Wettability:

The porous structure significantly improves the powder’s ability to absorb water quickly, especially in cold liquids.Improved Dispersibility:

Increased particle size and reduced cohesiveness allow the powder to disperse more uniformly without clumping.Better Homogeneity:

Agglomeration contributes to consistent color, bulk density, and flavor perception in every serving.Reduced Density Mismatch:

By minimizing differences in particle density among ingredients (e.g., cocoa, sugar, micronutrients), it prevents segregation during handling and packaging.

How Particle Binding in Agglomeration Creates a Uniform and Readily Soluble Structure

Agglomeration is a particle engineering process in which fine powder particles (such as cocoa or sugar) are combined using a wetting agent (typically water, steam, or a lecithin-based binder) to form larger, porous, and more stable agglomerates. This transformation directly improves the functional and sensory quality of instant beverage powders.

In the production of instant cocoa powders, agglomeration is not only a tool for improving technical performance, but a foundational requirement for delivering a seamless, repeatable, and high-quality consumer experience.

What Is Cocoa Powder Alkalization (Dutching) and Why Does It Matter ?

It is a process that uses alkaline solutions to alter the structure of cocoa, changing its color, flavor and stability This process improves the overall quality of the final product.

To learn how different types of alkalis affect the final product quality, read here.

- Related articles

The Role of Agglomeration in Enhancing the Quality of Instant Beverage Powders

Improving Flavor Uniformity, Dispersibility and Product Stability with Agglomeration Technology

In the food industry—particularly in the production of instant beverage powders, nutritional supplements, and infant formula—reconstitution performance is defined by several key parameters, including dispersibility, wettability, and rapid solubility. These characteristics directly influence the overall quality and usability of the final product.

Many non-agglomerated powders suffer from poor performance in contact with water due to unfavorable physical properties.

Common Issues in Non-Agglomerated Powders :

Fine particles with poor particle size distribution

Density differences between formulation components

High surface fat content (as found in cocoa powder), which impairs wettability and delays dissolution

Agglomeration technology addresses these challenges by creating porous, cohesive structures:

Formation of interstitial voids between particles allows faster water penetration and more efficient dissolution

Controlled binding of fine particles improves structural uniformity and reduces sedimentation

Use of sugar crystals as nucleation sites—especially in fluidized bed systems—supports stable granule formation

Improved dispersibility and flavor uniformity with each serving

Reduced tendency toward lumping and component segregation during processing and storage

How Particle Binding in Agglomeration Leads to a Uniform and Readily Soluble Structure

According to experimental findings, the composition of raw materials (including cocoa fat content, sugar type, lecithin ratio, and moisture level), along with precise control of process parameters (such as drying temperature, residence time, and water addition), significantly affect bulk density, particle size, and granule hardness.

Increased water content during agglomeration typically results in longer process times and lower final bulk density, but leads to improvements in flavor and color uniformity, while also minimizing segregation. These attributes are particularly critical in formulations designed for children’s products or sports nutrition, where quick preparation and consistent sensory experience are essential.

1. Spray Agglomeration

A process in which fine and dusty powders are converted into larger, porous granules by spraying a liquid binder followed by simultaneous drying. This method is particularly effective for producing instantized products.

Key Features :

Increases particle size and reduces dust generation

Creates a porous structure with a high surface area

Significantly improves wettability, reconstitution speed, and performance uniformity

Suitable for applications such as instant beverages, infant formula, nutritional supplements, sweeteners, and soluble food powders

🔗 See Benković & Bauman (2011) for data on agglomeration effects.

2. Spray Drying

A conventional method for converting liquids, emulsions, or suspensions into dry powders with very fine particles.

Advantages:

Ideal for large-scale production with consistent particle quality

Allows processing of temperature-sensitive compounds under controlled thermal conditions

Limitations:

Produces fine and lightweight particles

Can lead to dusting and low solubility, particularly in instant applications

3.Granulation

A method used to create larger, more mechanically stable particles, typically through the addition of moisture or binders.

Advantages:

Improves mechanical stability and reduces stickiness

Suitable for tablet production or powders requiring precise dosing control

Limitations:

May offer less functional uniformity or reconstitution efficiency compared to agglomeration

4. Encapsulation

A technology for encasing sensitive compounds such as vitamins, flavors, or probiotics to protect them from environmental stressors.

Advantages:

Shields active ingredients from heat, oxygen, or moisture

Enables controlled release during processing or digestion

Limitations:

Limited effect on solubility or dispersibility in water

May have restricted functionality in instant applications

Comparison: Agglomeration vs Spray Drying, Granulation and Encapsulation

Advantages and Challenges of Agglomeration Technology in Instant Food Powder Formulation

Advantages of Spray Agglomeration Technology

Spray agglomeration in a fluidized bed system offers multiple advantages that contribute to enhanced consumer experience, process efficiency, and supply chain optimization.

Improved Flowability :

The porous structure of agglomerated granules reduces inter-particle friction, enabling free-flow behavior in filling lines and mixers . a critical factor for automation and high-speed production environments.

Enhanced Re-dispersibility :

Thanks to increased surface area and interstitial voids, agglomerated powders rehydrate rapidly in water ( even in cold conditions ) without lump formation.

Reduced Dusting :

By transforming fine, loose particles into more cohesive granules, agglomeration significantly lowers airborne dust, minimizes material loss, and reduces occupational and environmental risks.

Increased Bulk Volume :

The expanded spacing between particles results in a higher volume-to-weight ratio, offering a “fuller, lighter” package appearance , an important sensory and visual cue for consumers.

Optimized Particle Size Distribution :

Controlled spray application leads to a more uniform particle size distribution, which improves consistency in flow, solubility, and dosing behavior.

Challenges of Agglomeration Technology

Despite its advantages, agglomeration especially at an industrial scale, presents several challenges that must be addressed during process and product design:

High Equipment Investment :

Fluid bed agglomerators require precise control over air temperature, humidity, and spray rate. This capital-intensive setup may be cost-prohibitive for small to medium-scale producers.

Energy Consumption in Drying Phase :

Post-spray drying typically demands continuous heat input (usually 50–80°C), resulting in higher energy use compared to traditional drying methods.

Risk of Structural Inconsistency :

Inadequate control of spray flow rate or residence time can lead to non-uniform agglomerate formation, causing poor solubility, unstable granules, or sedimentation in the final product.

Sensitivity to Raw Material Properties :

Particles with high surface fat content (such as cocoa powder) or components with large density differences (e.g., crystalline sugars vs. light powders) are prone to agglomeration defects like segregation or uneven binding.

Technologies and Equipment Used in the Agglomeration Process

Choosing the appropriate agglomeration technology is not solely limited to selecting a specific machine. Rather, it involves a broader set of decisions regarding product characteristics, raw material types, process conditions, and desired granule structure.

Key Factors in Selecting the Right Technology

(Material Type, Moisture, Temperature, Spray Rate)

Selecting the right agglomeration method for food powders—especially instant products—depends on multiple formulation and process variables. In fluid bed spray agglomeration, precise control of these parameters is essential for achieving optimal product performance.

According to Glatt’s technical paper “Spray Agglomeration – Optimal Instant Properties for Granular Powders”, the following factors play a critical role in selecting the appropriate technology and designing a successful agglomeration process. The insights below are based on process expertise shared in that reference.

1. Binder Solution – Type and Quantity

The concentration and composition of the liquid binder (e.g., lecithin solution or sugar syrup) directly affect droplet formation, spray duration, and the uniformity of particle wetting.

Inadequate binder quantity may lead to incomplete agglomeration; excessive binder can cause over-wetting and structural collapse during drying.

2. Process Temperature and Thermal Sensitivity of Ingredients

The drying temperature must be carefully adjusted to avoid damaging heat-sensitive compounds such as flavors, vitamins, and active ingredients.

For most food powders, drying is performed between 50–80°C, depending on material sensitivity and targeted porosity.

3. Binder Solution – Type and Quantity

The concentration and composition of the liquid binder (such as lecithin or sugar solutions) directly affect droplet formation, spray duration, and particle wetting behavior during the agglomeration process.

Binder quantity must be carefully adjusted; insufficient binder leads to weak agglomerates, while excess moisture can cause over-wetting and structural breakdown.

4.Inlet Air Speed and Droplet Size

Droplet size is one of the primary parameters affecting particle growth and agglomerate morphology.

Higher inlet air velocity enhances particle fluidization, leading to better distribution and structural uniformity during spray agglomeration.

Strategies for Designing Products with Fast Dissolution and a Distinctive Sensory Experience

Developing Products with High Reconstitution Ability in Cold Milk/Water

The microstructure of instant powders plays a crucial role in determining how quickly and uniformly a product dissolves. For cocoa-based formulations, this structure directly affects sensory consistency and dosing precision.

Key features of a well-structured instant beverage powder include :

Porous agglomerate design that promotes rapid rehydration, especially in cold liquids

Optimized particle size distribution and flowability to ensure consistent dosing and smooth dispersion

Controlled layering of ingredients during agglomeration to improve flavor uniformity

Engineered performance that sustains sensory consistency throughout the product shelf life

📌 Achieving fast reconstitution in cold milk depends on integrated control over raw material composition, binder system, and spray-drying/agglomeration parameters. This balance enables efficient preparation and consistent user experience without the need for vigorous stirring or added heat.

Conclusion: How Smart Powder Design Creates a Seamless Consumer Experience

In the formulation of instant powder products—especially beverages designed for cold-water or cold-milk reconstitution—the interaction between particle structure, agglomeration processing, and raw material selection is what ultimately defines product success.

Through fluid bed agglomeration, combined with precise control over process parameters (such as droplet size, spray pattern, and fluidization behavior), and a data-driven approach to ingredient selection, product designers can engineer powders that consistently perform well in real-use scenarios.

Ultimately, what defines a satisfying consumer experience is not just the taste, but the fact that each serving dissolves easily, reconstitutes reliably, and delivers consistent sensory quality throughout the product’s shelf life.