Production of Bensdorp cocoa powder

Bensdorp cocoa powder production process

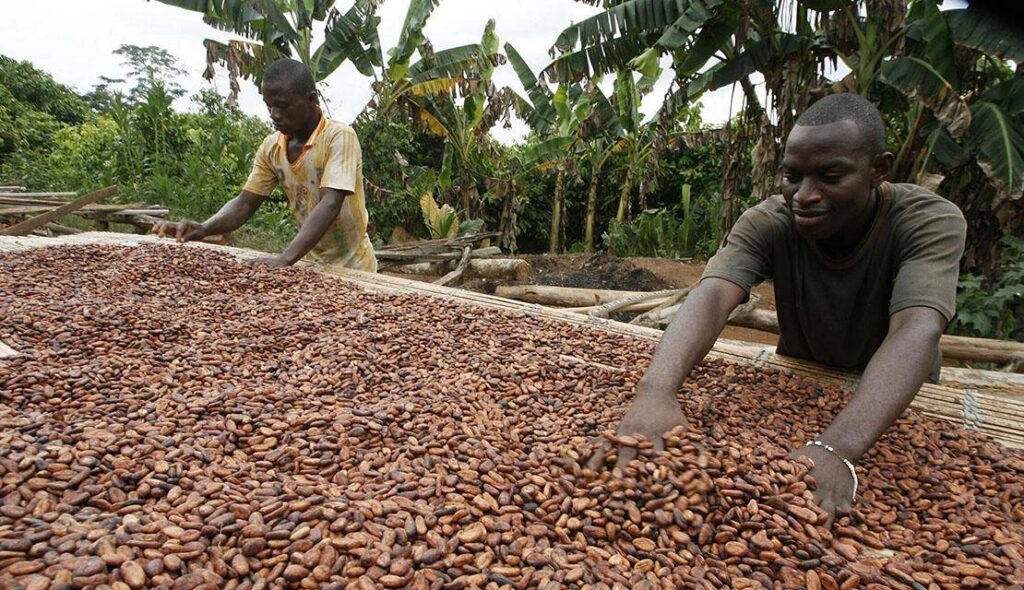

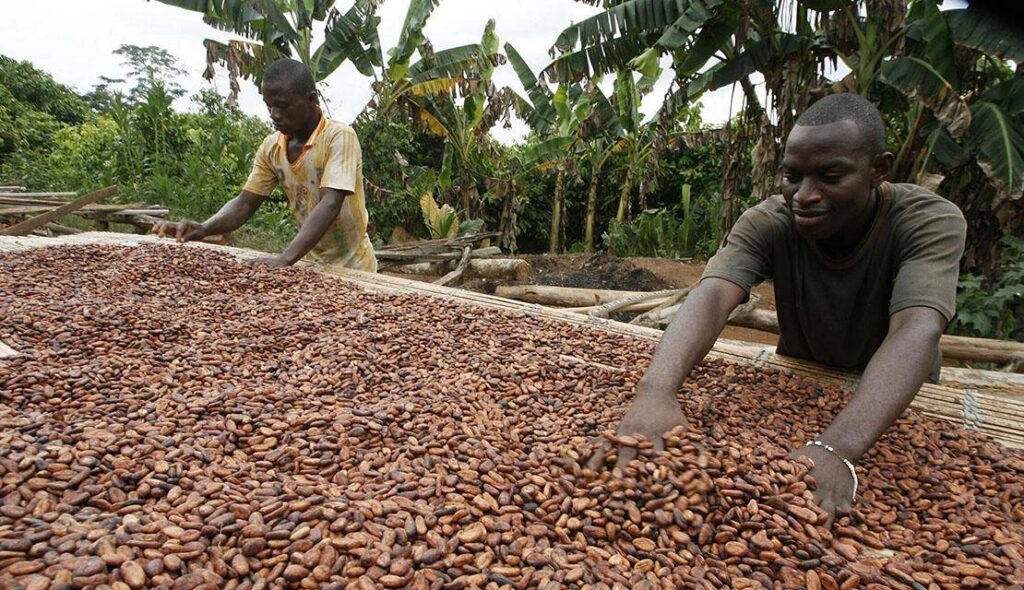

Global presence has taught Bensdorp how to source premium cocoa bean products and work with the most committed cocoa farms. With only one goal: to share the best experience of this beautiful cocoa product with the world and transform cocoa beans into the highest quality cocoa powders.

study guide

Nearly 180 years of passion and dedication at Barry Callebaut in the Netherlands have made Bensdorp a master of cocoa. With a meticulous selection of cocoa beans from the world’s finest plantations, Bensdorp seeks to deliver an authentic and rich cocoa flavor in its products. This superior quality is evident in Bensdorp’s cocoa powder, chocolates, and other products.

The combination of first-class West African cocoa beans

Bensdorp, with its long history of producing cocoa powder, attributes the exceptional quality and taste of its products to a unique and precise blend of three specific cocoa bean varieties from West Africa. This exclusive blend allows Bensdorp to guarantee a consistent color, rich flavor, and enduring quality in all its products.

The combination of first-class West African cocoa beans

Bensdorp, with its long history of producing cocoa powder, attributes the exceptional quality and taste of its products to a unique and precise blend of three specific cocoa bean varieties from West Africa. This exclusive blend allows Bensdorp to guarantee a consistent color, rich flavor, and enduring quality in all its products.

Alkalizing or Alkaline Process Dutch Dutching

After cleaning, cracking, and winnowing the cocoa beans, only the purest, hand-selected cocoa nibs remain. These nibs can then be processed through the Dutching process to create alkalized cocoa powder, or roasted to produce natural cocoa powder. Barry Callebaut, after 180 years, continues to use Bensdorp’s time-honored 19th-century Dutch method for alkalizing the beans.

“While Barry Callebaut’s modern equipment is vastly different from the machinery used in the 19th century, the fundamental Dutching process remains unchanged. Dutching, or alkalization, refers to the process of treating roasted cocoa nibs with an alkaline solution (potassium or sodium carbonate). This process allows Barry Callebaut to enhance the color, flavor, and solubility of the final cocoa powder, making it perfectly suited for the confectionery and dairy industries.”

The magic of roasting

Roasting is done in small batches to preserve the cocoa’s original flavor. All the steps until now have been precursors to truly important flavor and color. But roasting is where the magic really happens. Roasting the cocoa nibs releases the intense chocolate flavor and all the distinctive aromas and colors that are deeply hidden within their core.

The choice of direct roasting over shell roasting to a temperature of 130 degrees Celsius is the magic performed by Bensdorp. It helps release the unique aroma, flavor, and color of the cocoa, leading to the production of higher quality cocoa powder. The use of a batch production system allows for precise control over the process quality. The supervision of Barry Callebaut experts over small production batches is a guarantee of Bensdorp cocoa quality.

Grinding, controlling the fineness of flawless cocoa powder

“Through a multi-stage grinding process, the roasted and winnowed cocoa nibs are transformed into cocoa liquor, a mixture of liquid and solid cocoa and cocoa butter. The standards that Bensdorp cocoa liquor must meet are among the highest in the cocoa industry, with a level of refinement far exceeding those used in the chocolate industry.”

Cocoa liqueur, Bensdorp's unique signature

Following the grinding process to produce cocoa liquor, a second mixing process ensues. Bensdorp cocoa liquors are blended together based on precise, measured formulas. Each Bensdorp cocoa liquor possesses unique color, flavor, and wettability characteristics, which, when combined, work in symphony to create a wondrous world of chocolate flavor, color, and texture.

Press, production of cocoa butter

“Hydraulic presses exert significant pressure to compress the cocoa liquor mixture, separating it into cocoa butter and cocoa cake. Depending on the pressing time and process parameters, the resulting cocoa cakes have a fat content ranging from 10 to 24 percent. At this stage, both the quality of the cocoa beans and the quality of their roasting play a crucial role. High-quality roasted cocoa beans allow for optimal pressing without compromising flavor during the process.”

Obtaining the best cocoa powder in the world

“At this stage, the powder grinding lines transform the cocoa cakes into cocoa powders with predefined particle size levels. However, this is where Bensdorp cocoa powder truly stands out from its competitors. Thanks to an innovative 3-step process, Bensdorp is able to produce the finest cocoa powder in the world. A cocoa powder with a medium fineness of 99.8% on a 75 µm/200 mesh sieve can take the taste, color, and delicious flavor of chocolate to a place that chocolate itself cannot reach.”

Stabilization and sometimes temperature

“Cooling ensures that the cocoa butter in the powder crystallizes properly, preserving the powder’s flavor and preventing color changes or clumping during storage. Thanks to Bensdorp’s special care in the cocoa powder cooling process, when you open a bag of Bensdorp, a delicious, fresh, and pure cocoa aroma permeates the entire room.”